VALVE ASSEMBLING

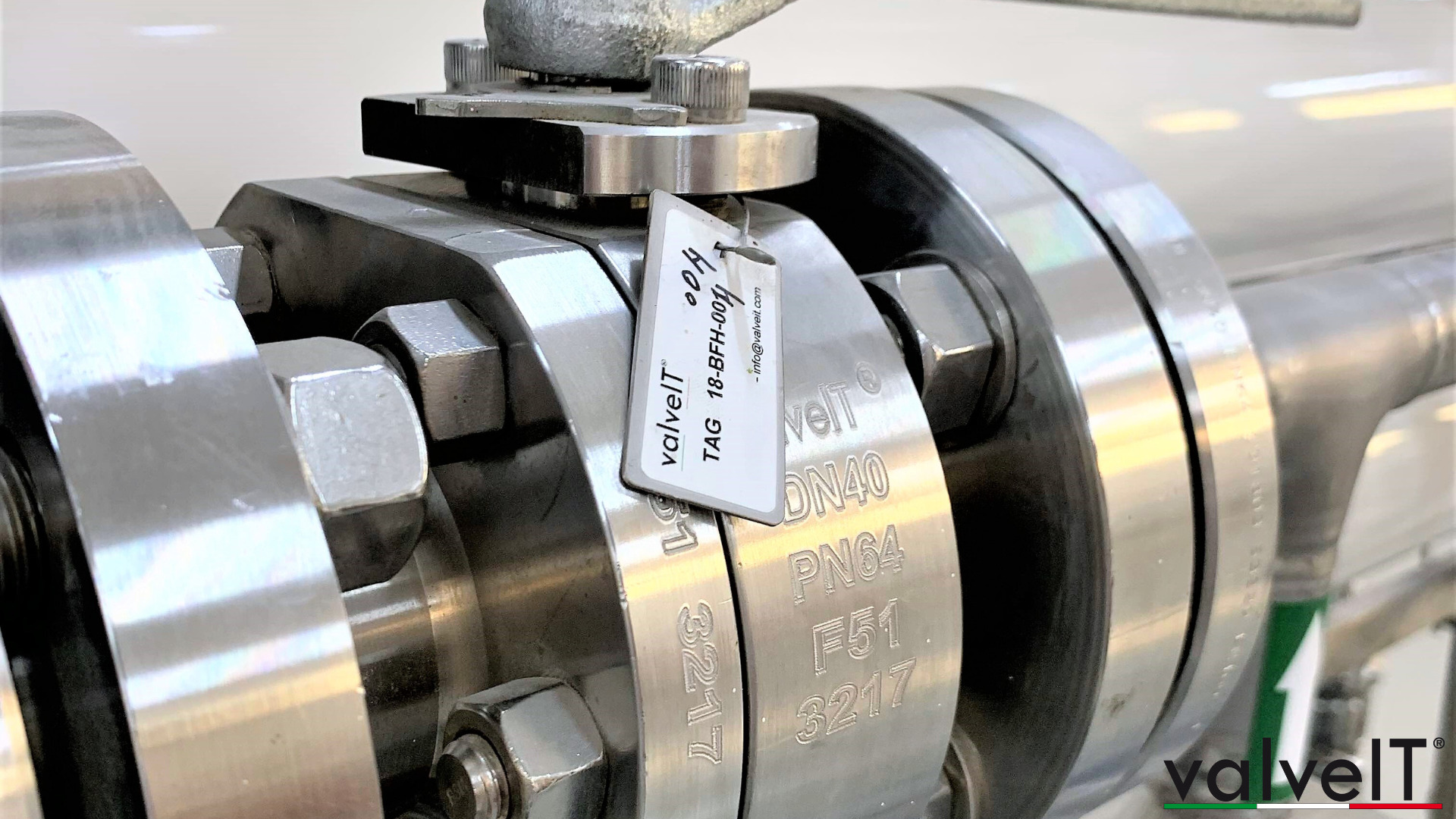

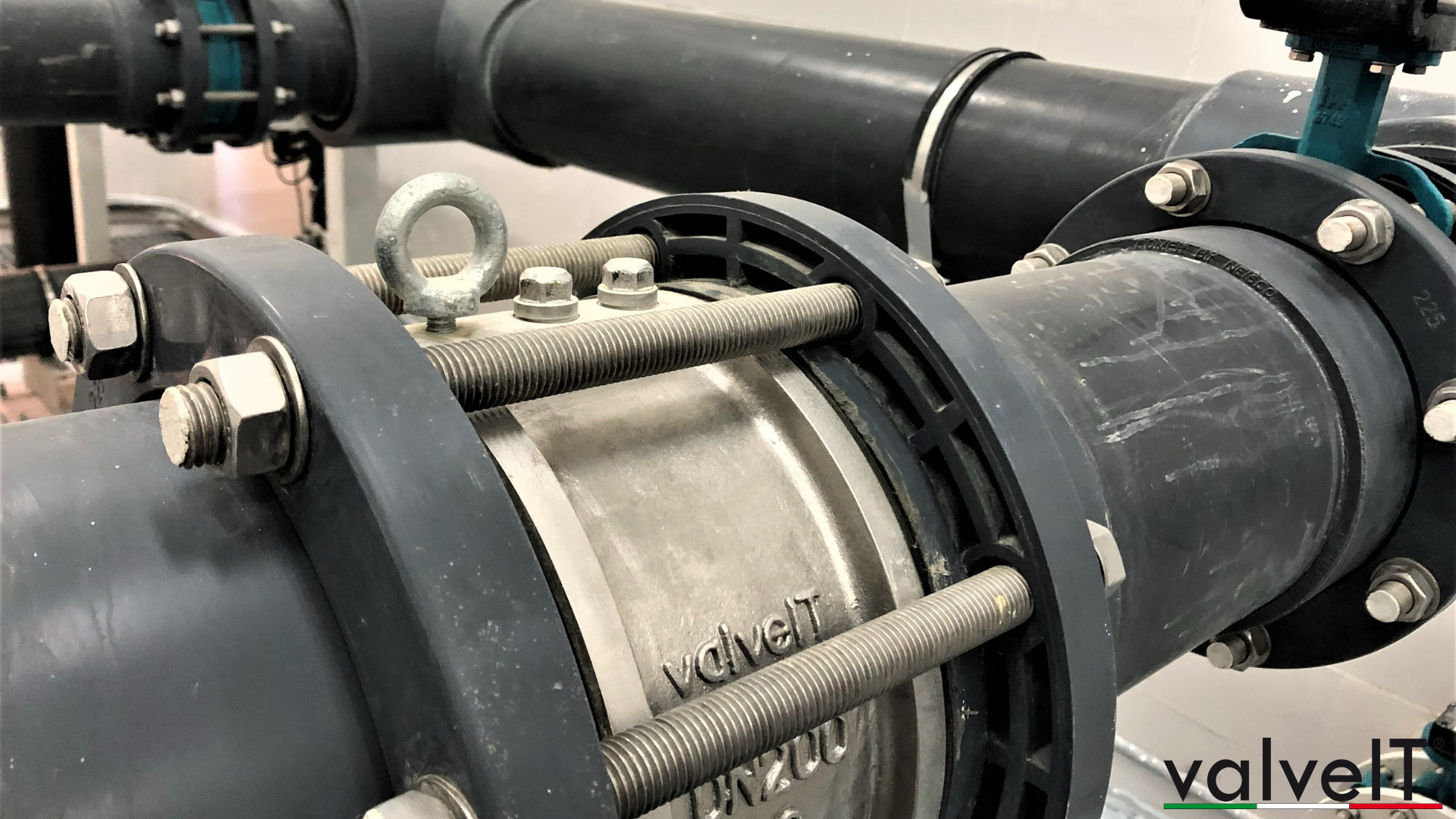

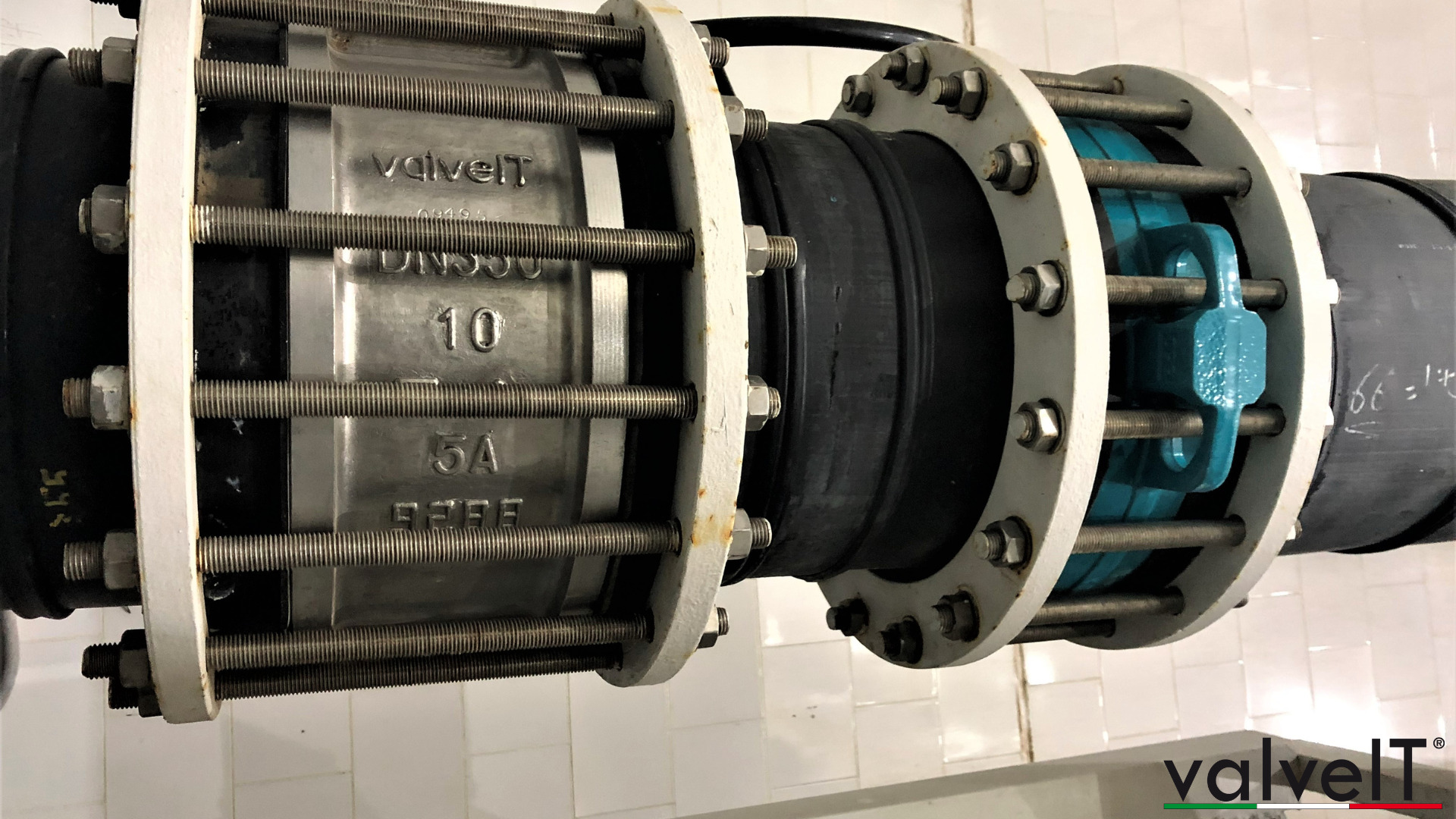

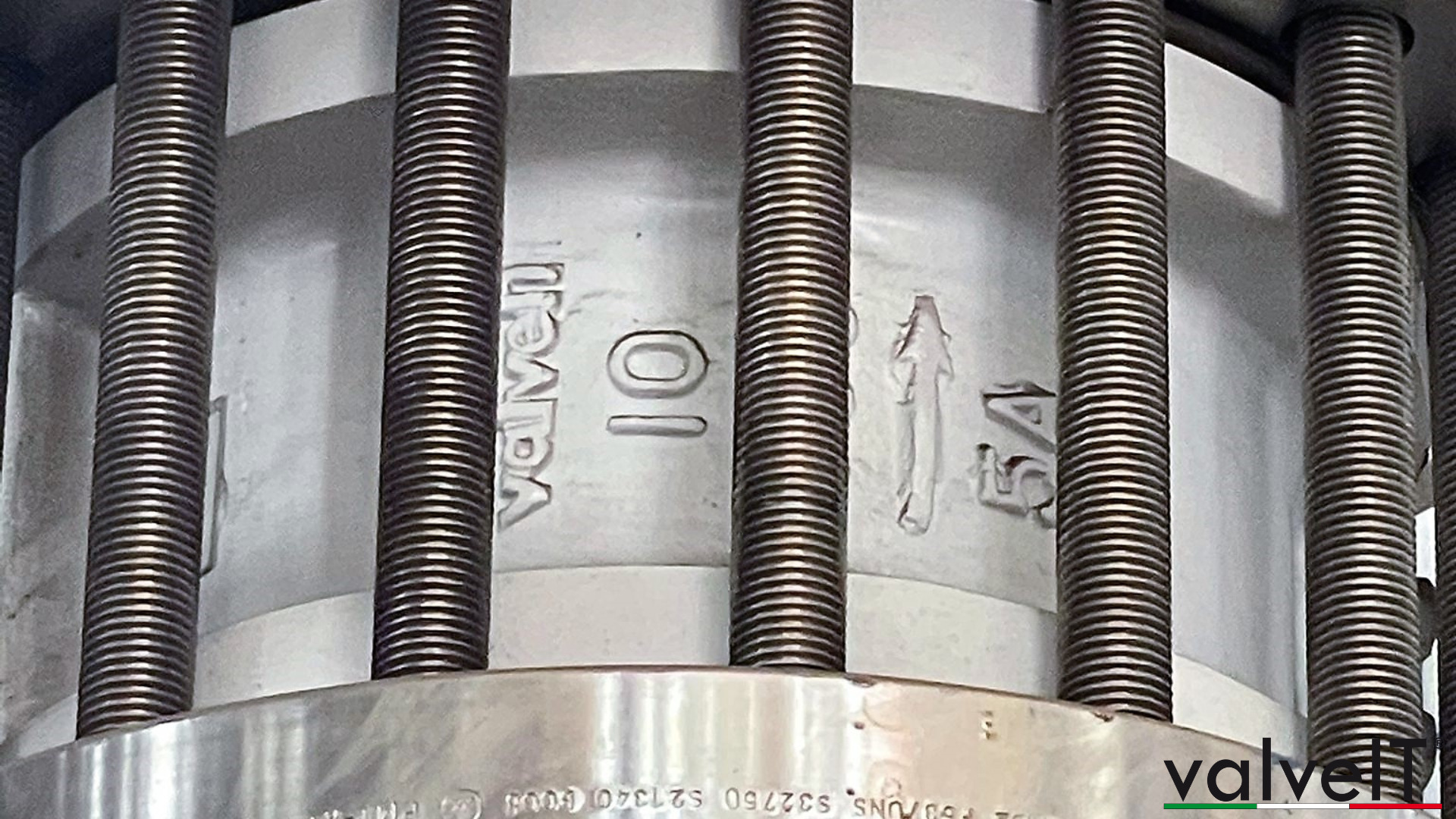

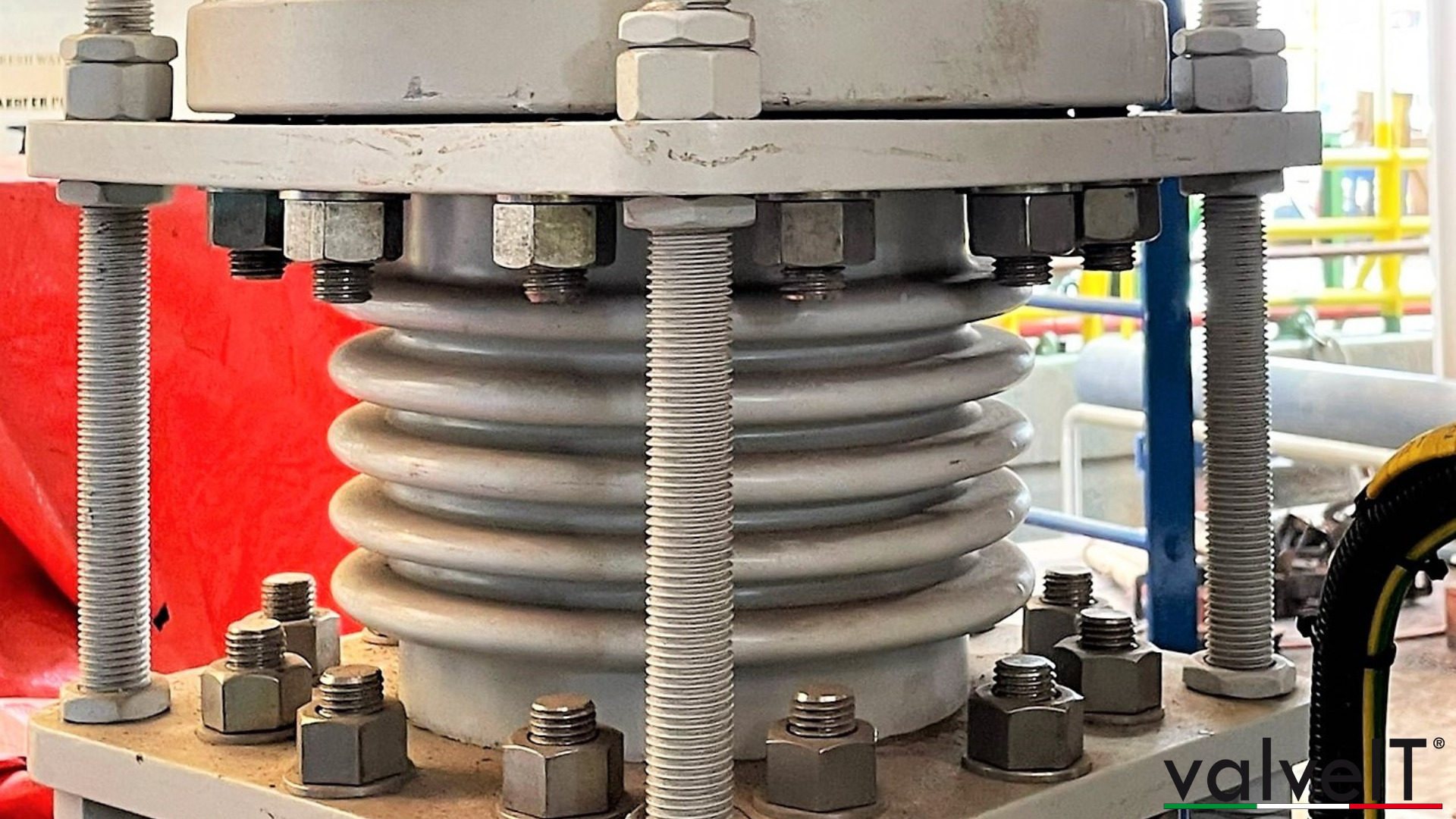

At the coating phase completion, the assembly process begins with the careful selection and inspection of valve components. valveIT’s skilled technicians thoroughly assess the quality and suitability of each component to ensure they meet the required standards.

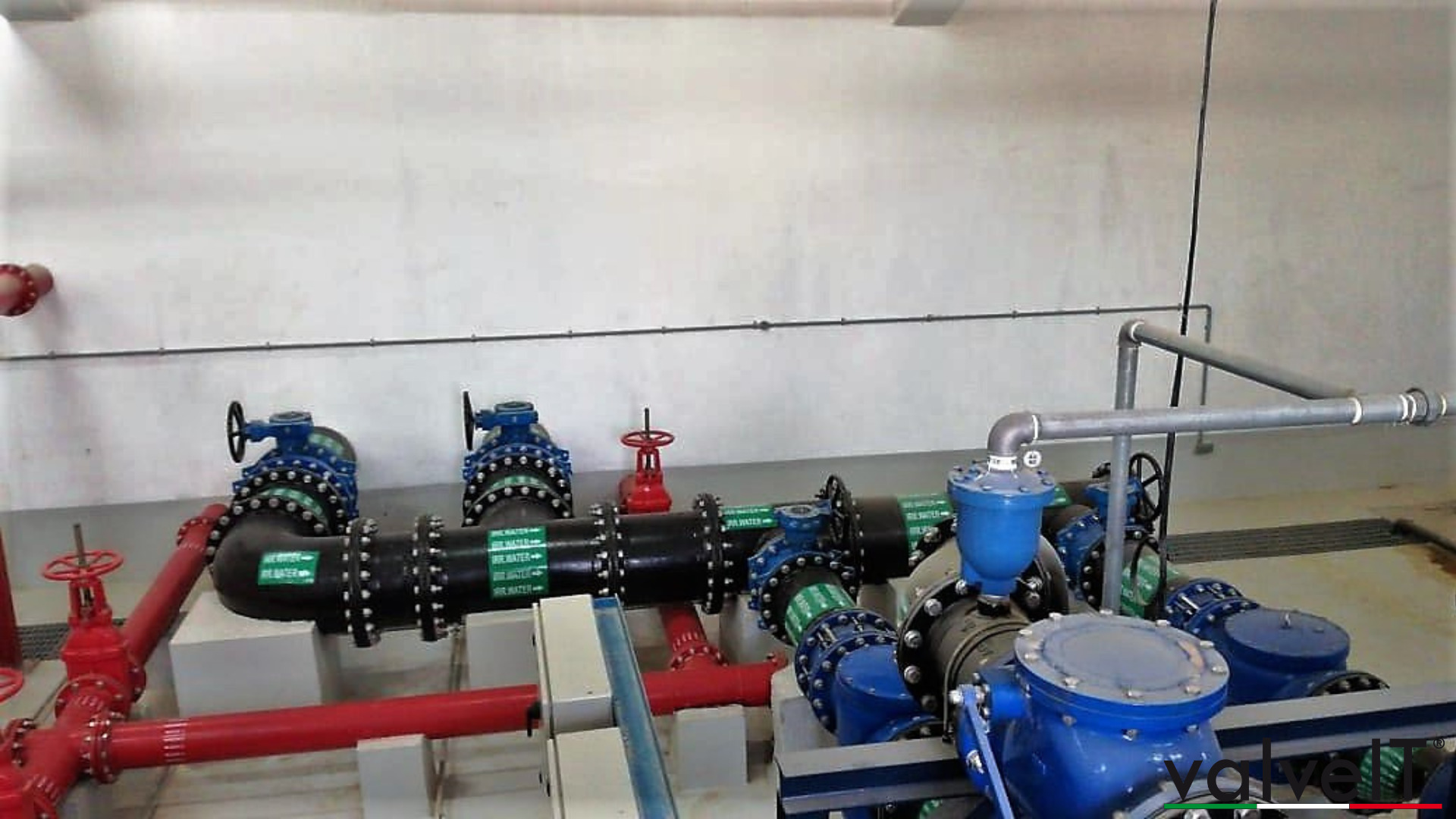

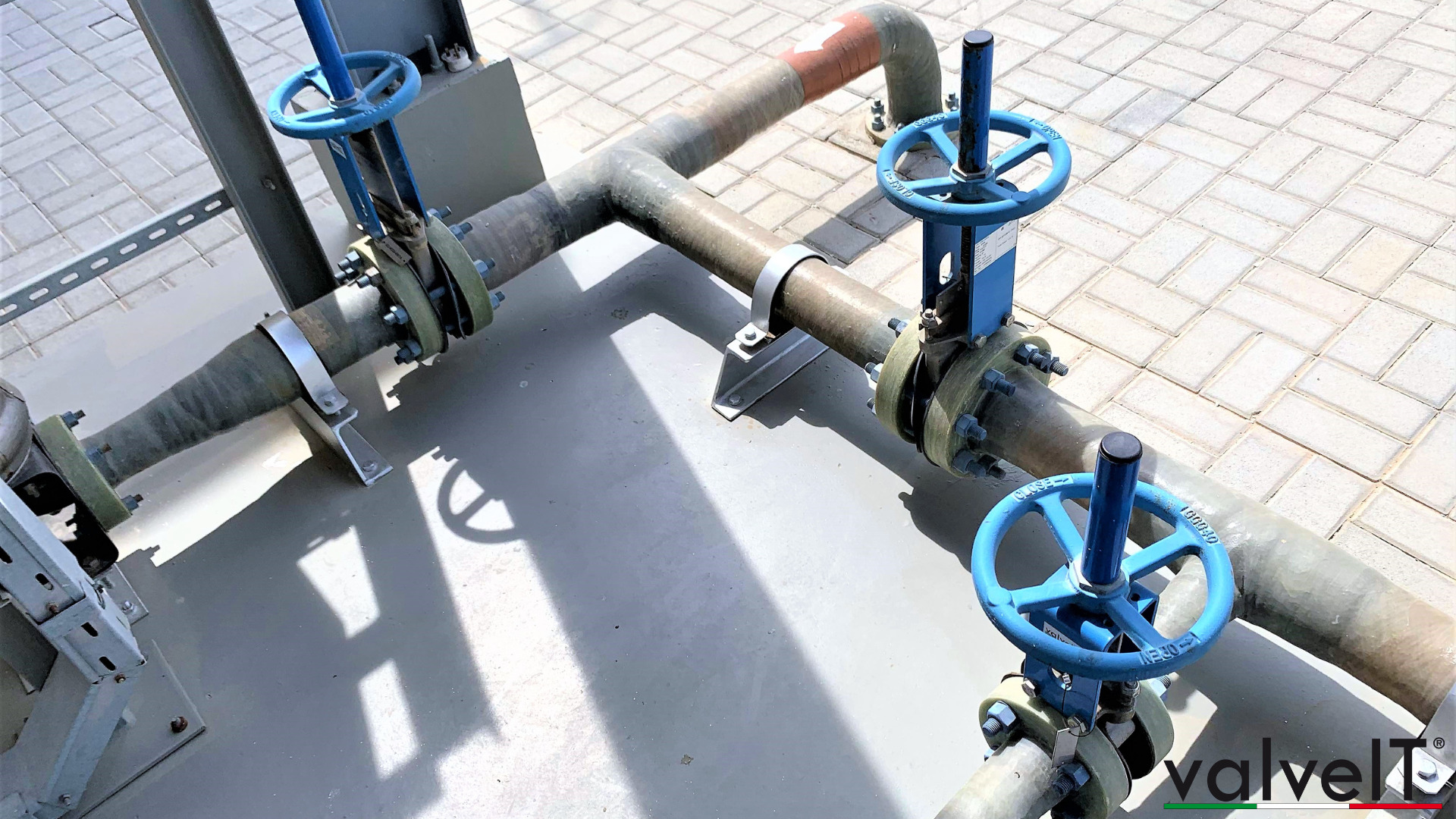

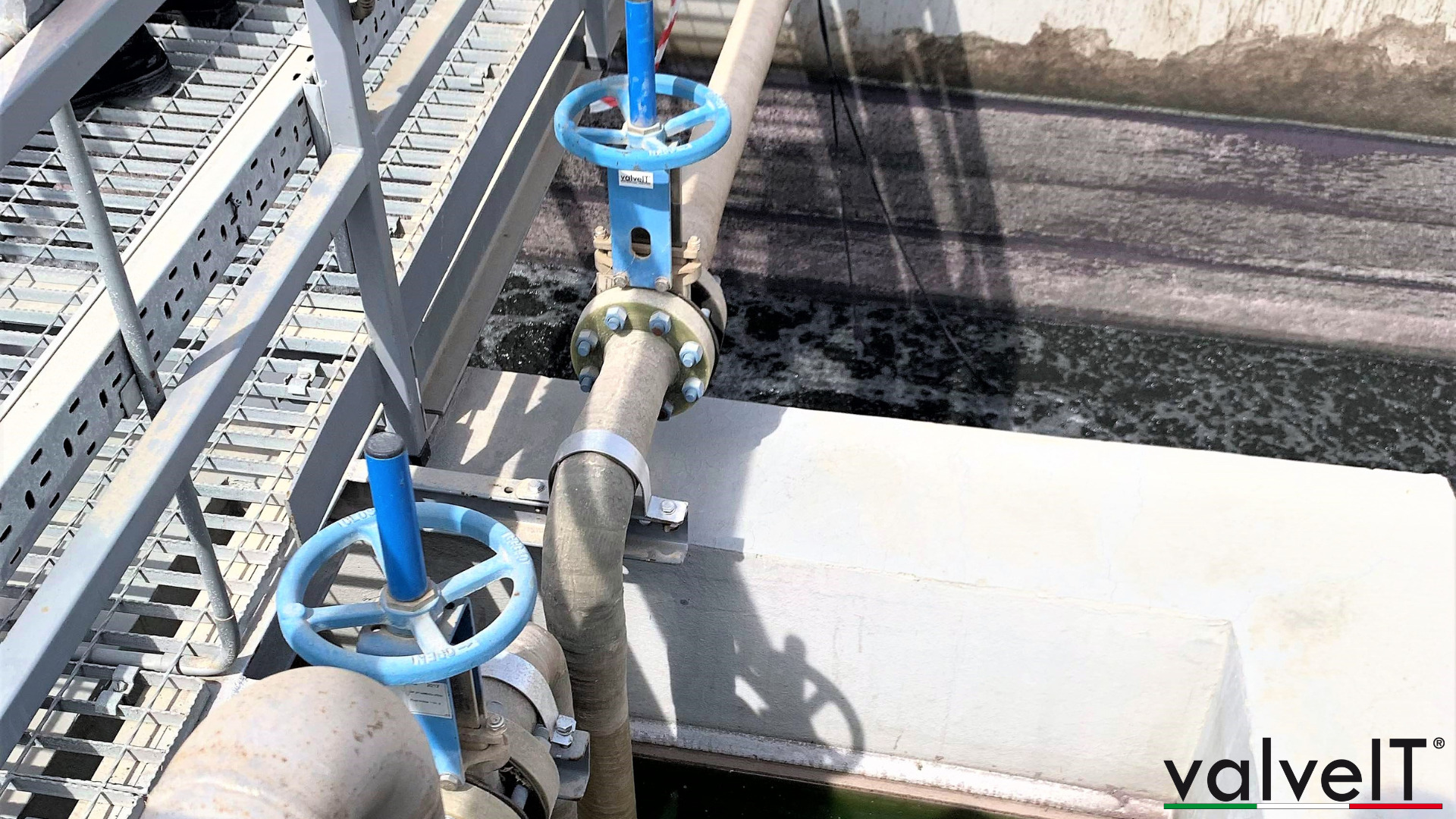

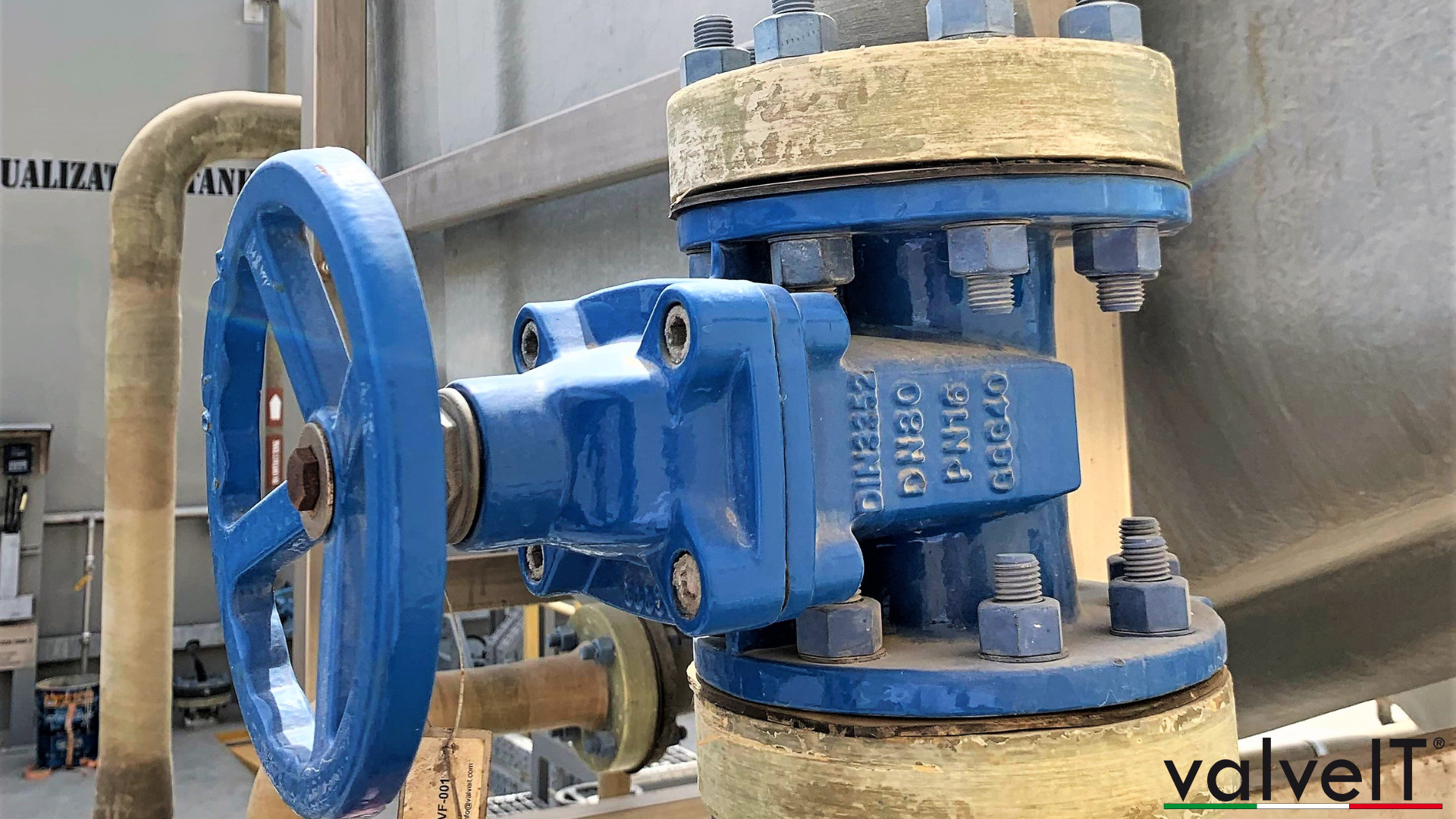

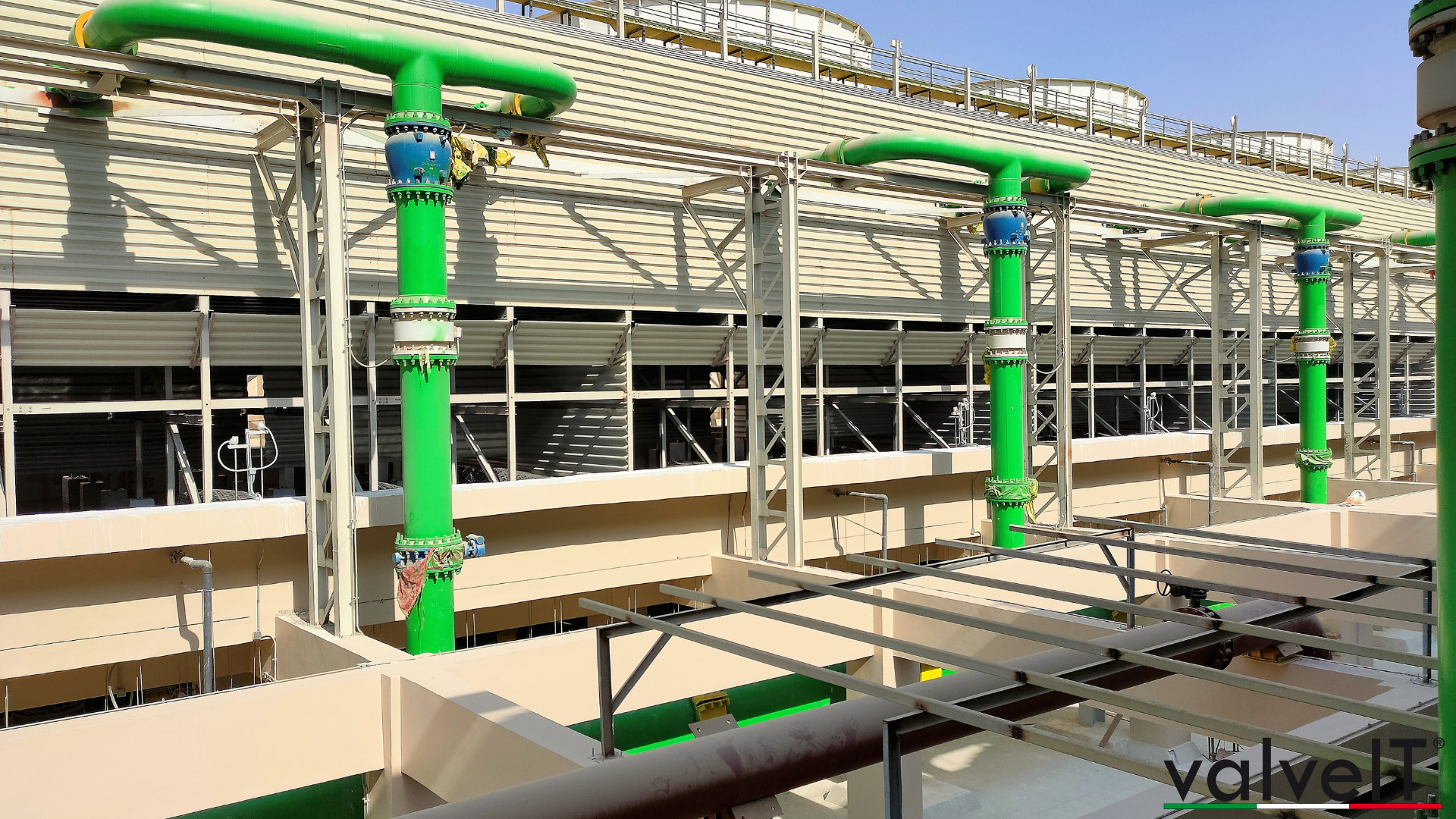

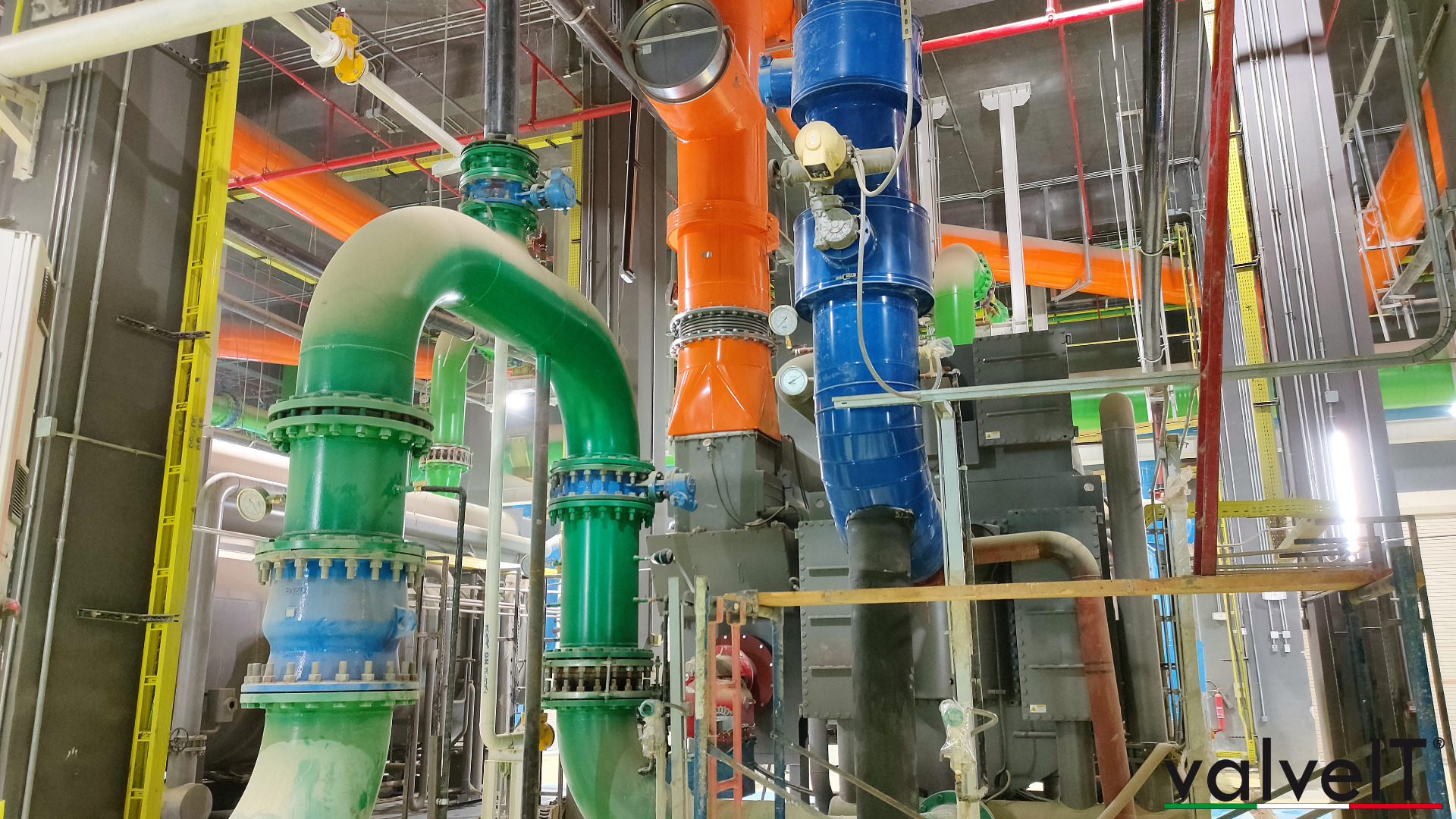

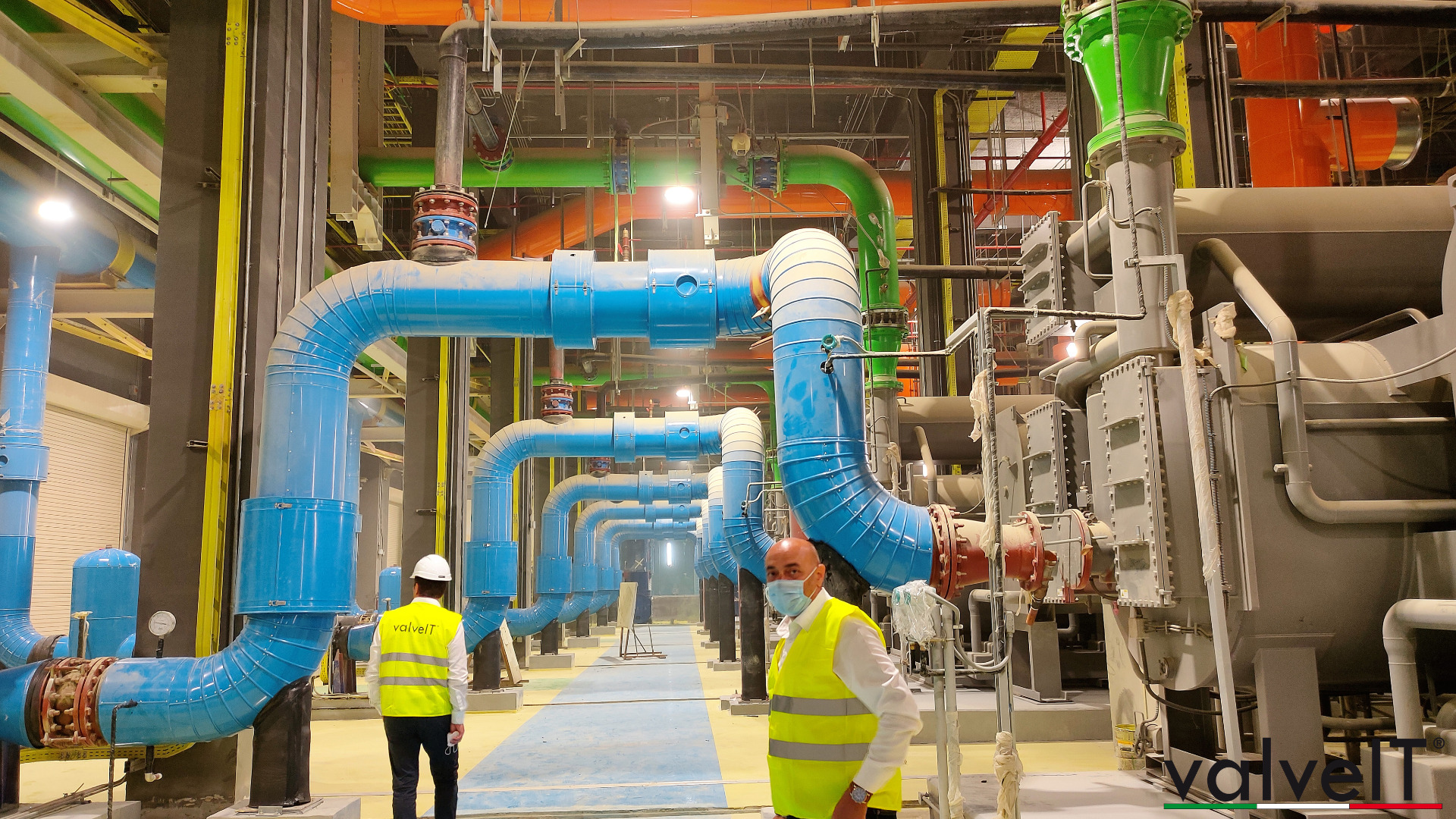

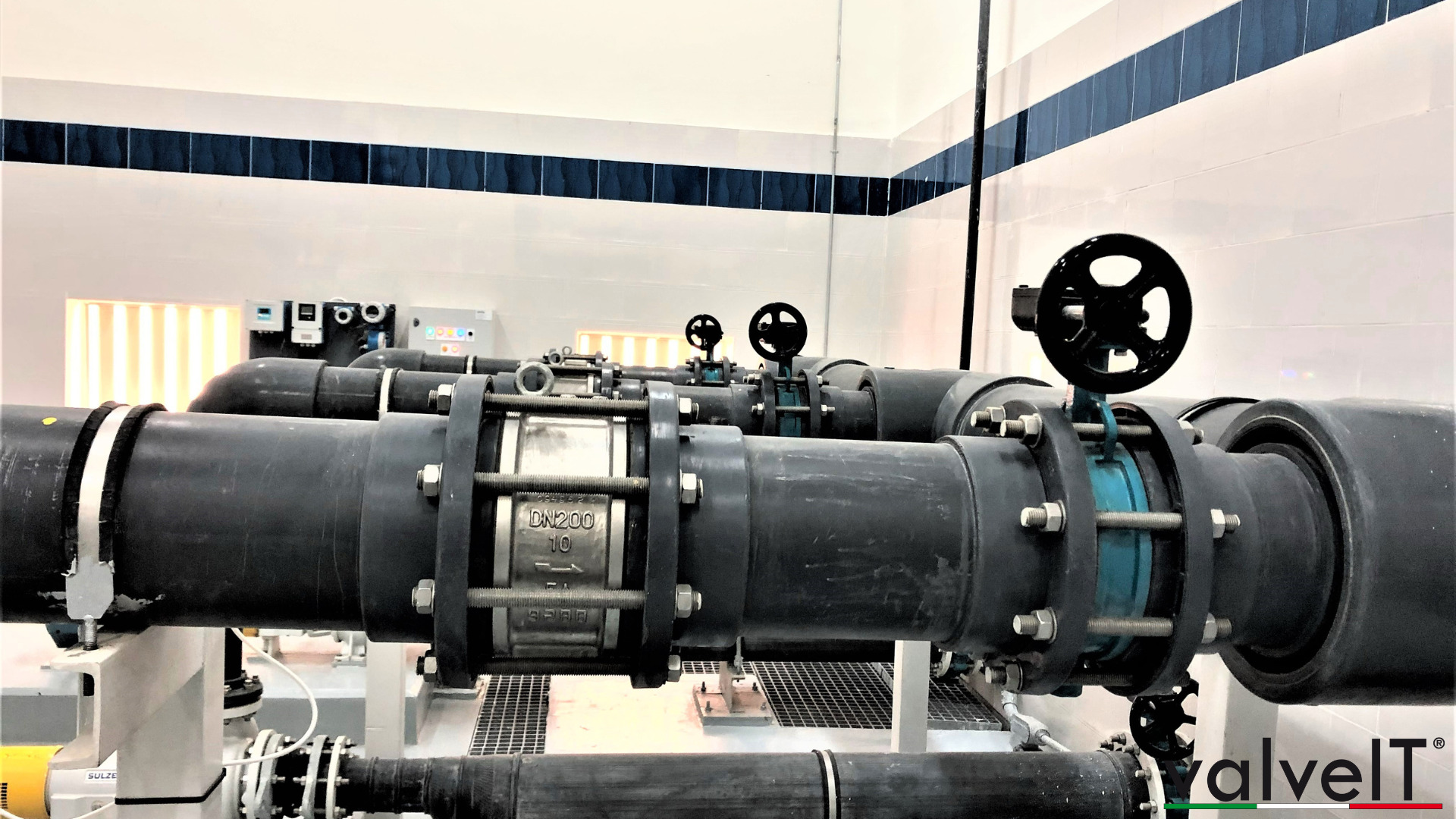

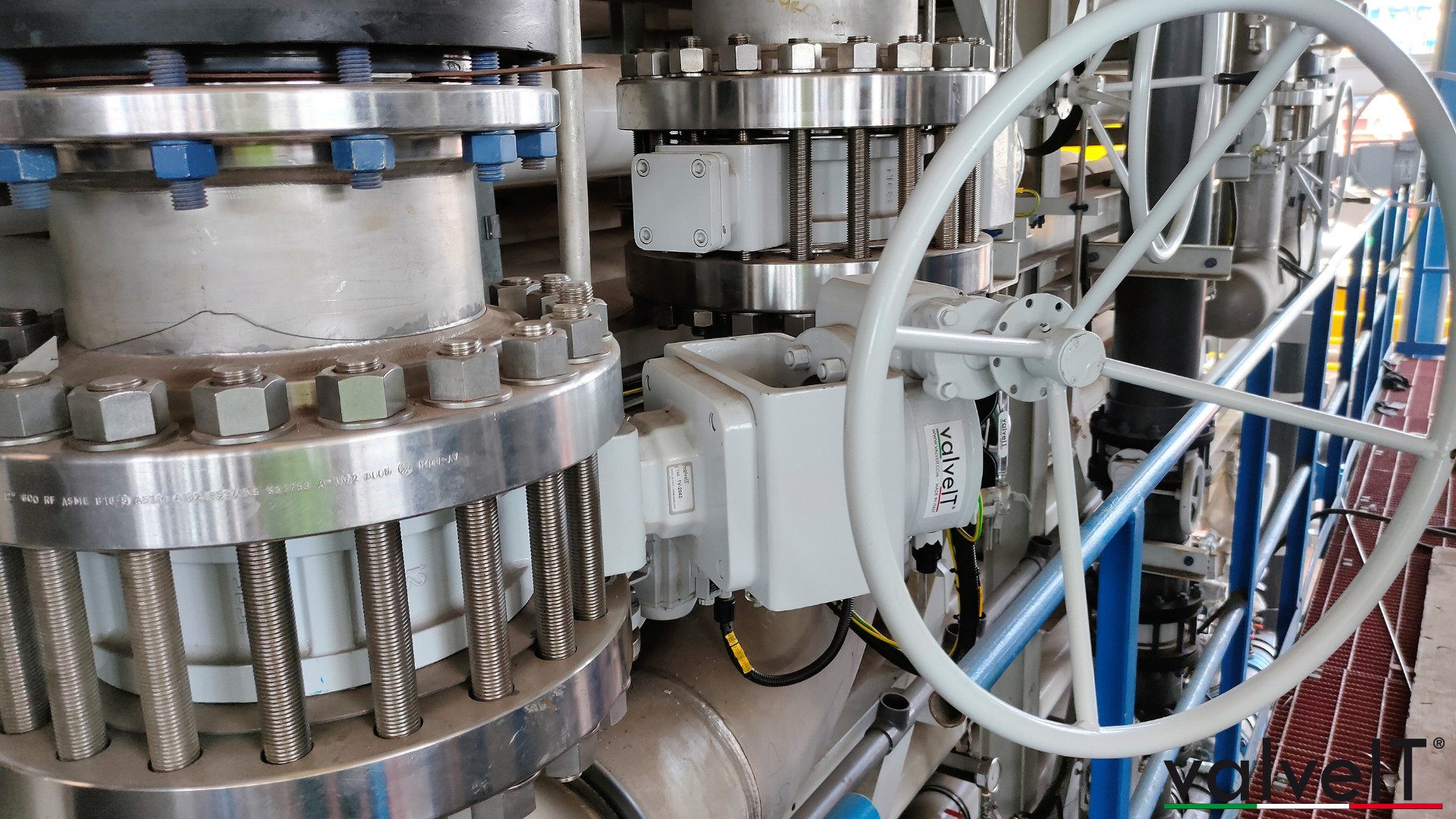

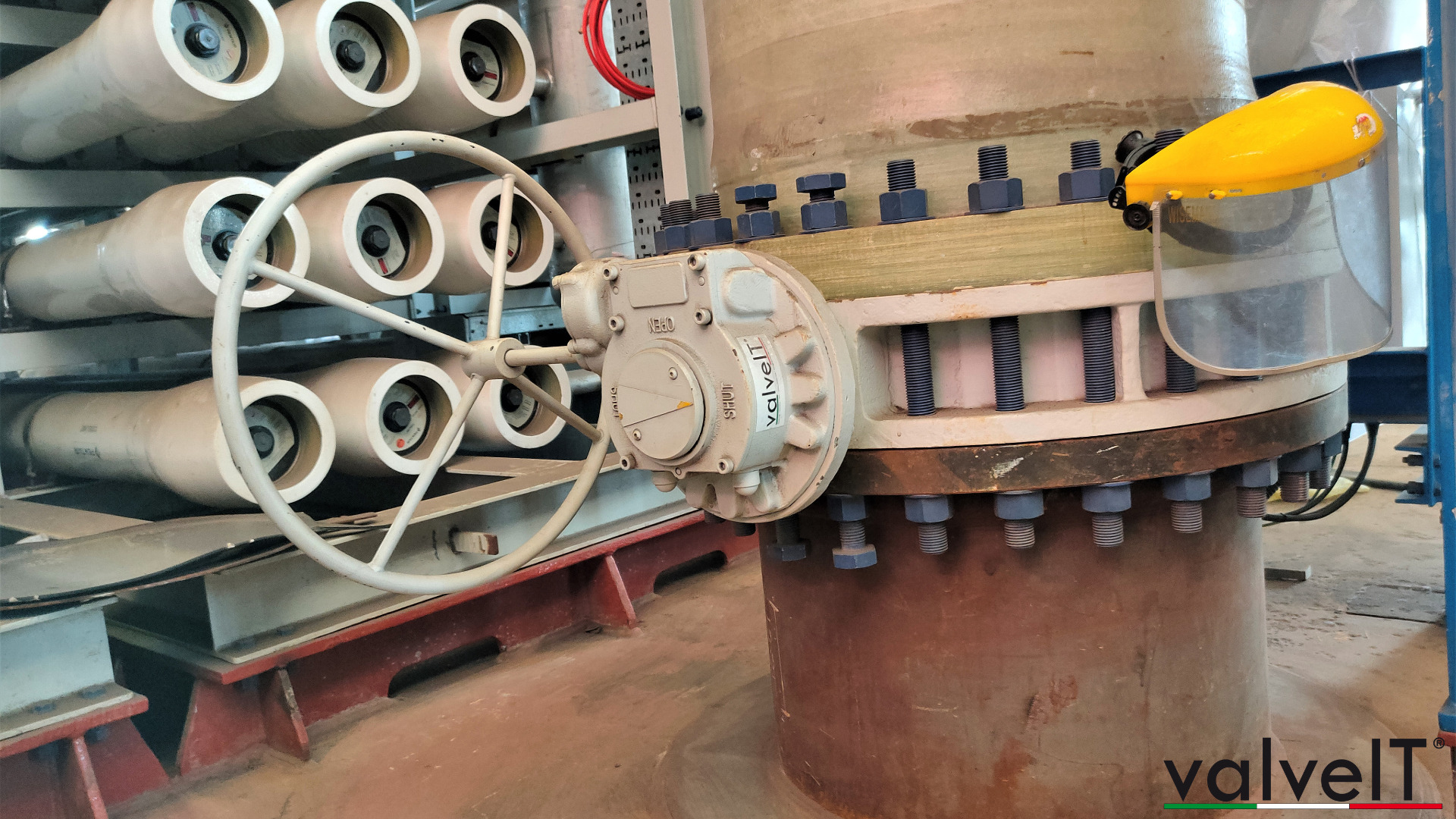

valveIT‘s engineers and technicians work closely to integrate components such as stem extensions, position indicators, limit switches, and manual overrides, as per the client’s requirements. These accessories enhance the functionality and control capabilities of the valves, enabling them to perform optimally in diverse industrial processes.

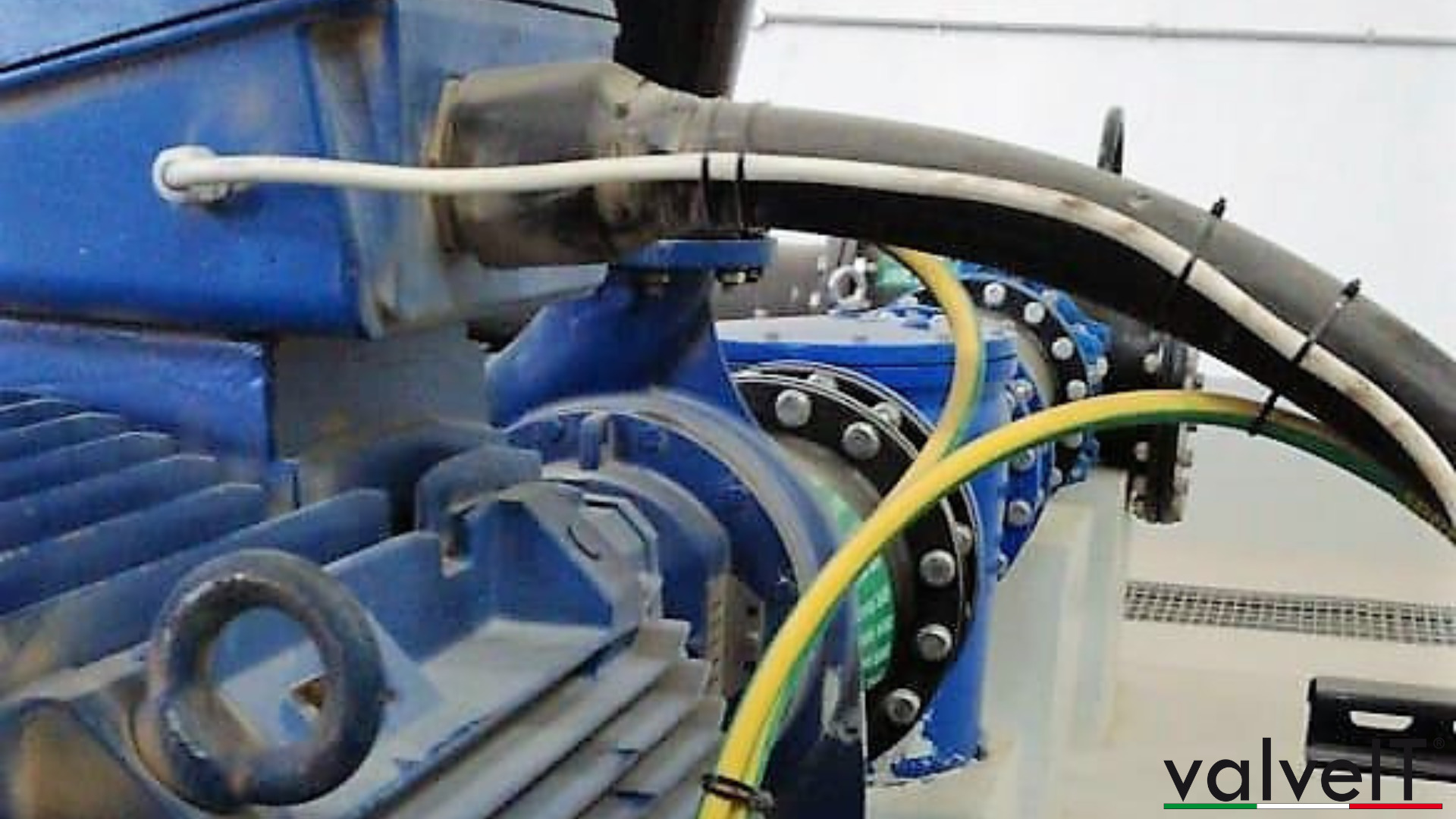

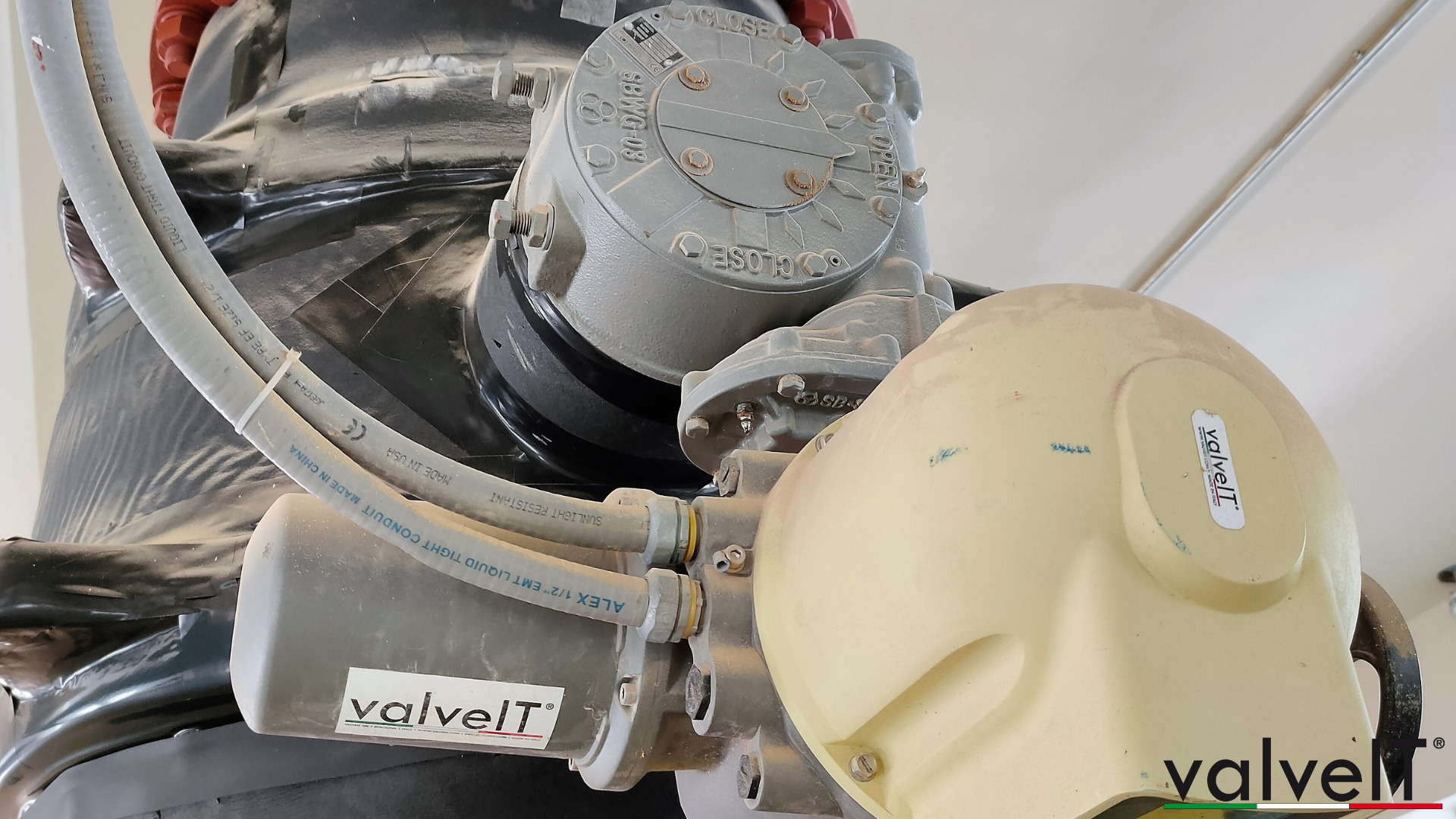

For valves that require electric motor actuation, valveIT expertly installs electric motors that are precisely matched to the valve’s torque and model. The electric motors are carefully calibrated to ensure smooth and accurate valve control. valveIT’s proficiency in integrating electric motors allows for seamless automation and remote operation, making the valve systems suitable for a wide range of industrial automation applications.

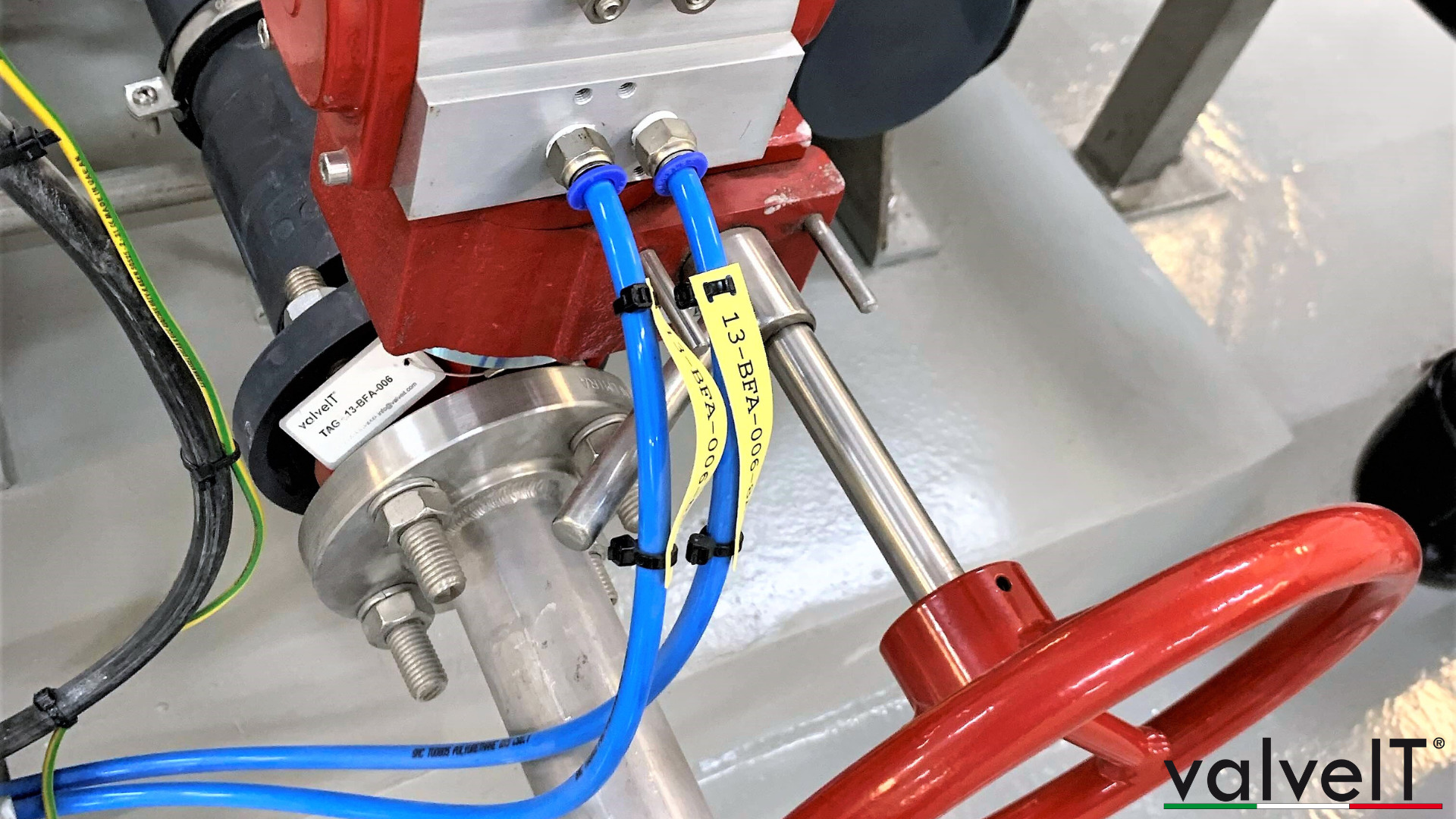

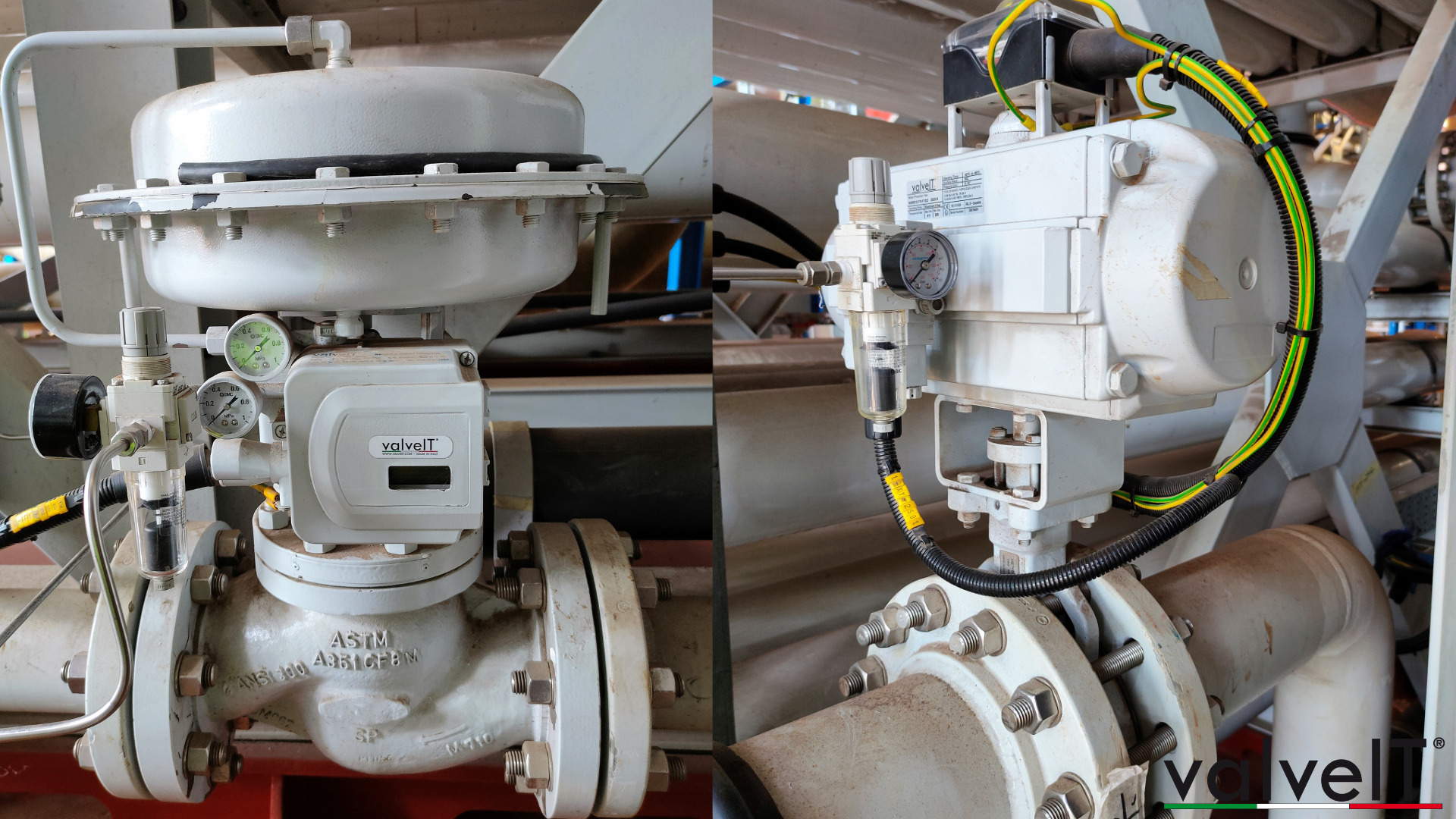

In cases where single acting or double acting pneumatic actuators are needed, valveIT ensures the precise assembly of the actuators onto the valves. The pneumatic actuators are selected to deliver efficient and reliable valve actuation, enabling quick response times and fail-safe operation (Fail Open – Fail Close – Fail Stay).

Throughout the assembly process, valveIT places great emphasis on quality assurance. Strict quality control measures are implemented at each stage to ensure that the assembly is accurate and free from any defects.