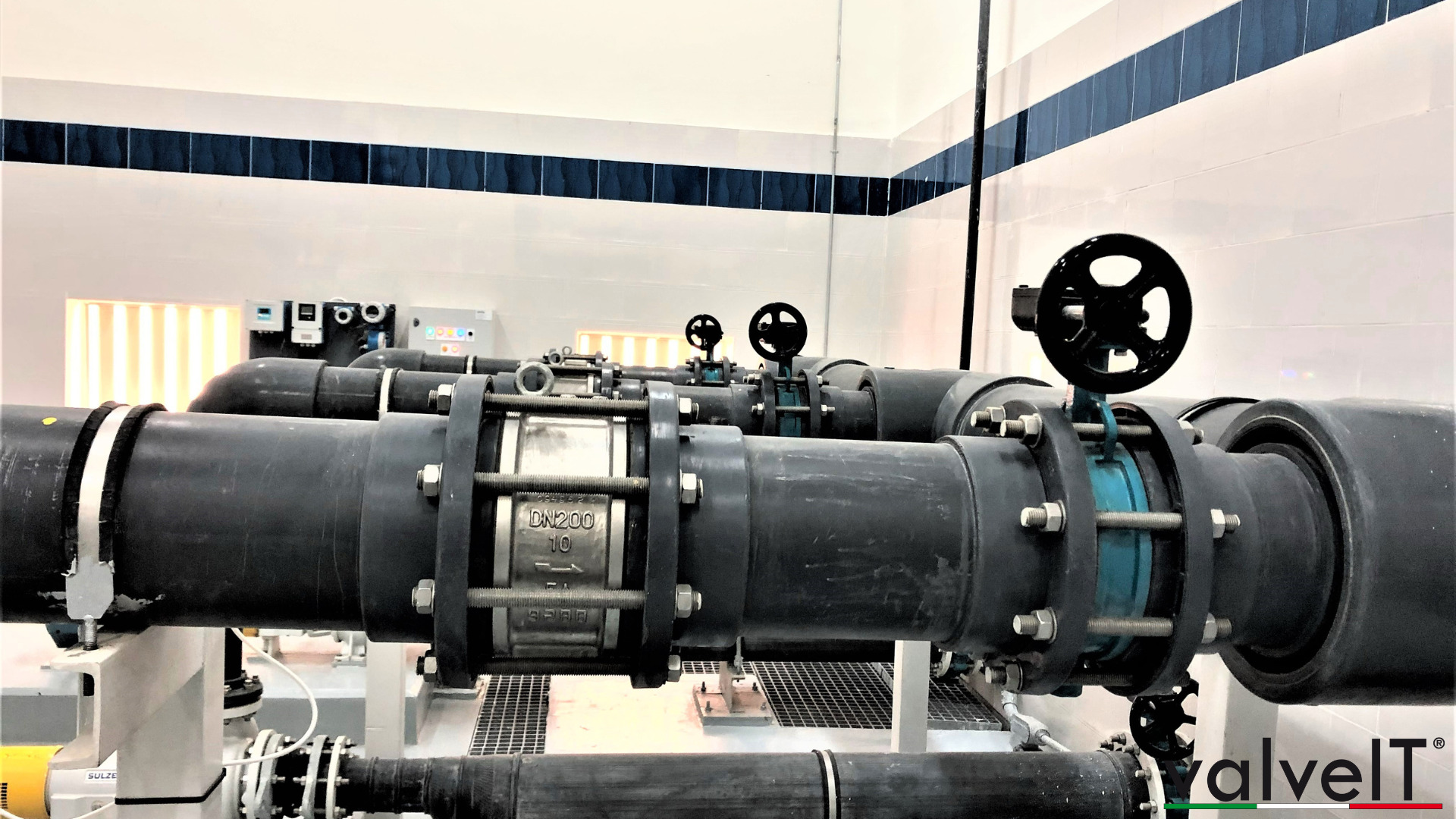

VALVE TESTING & INSPECTION

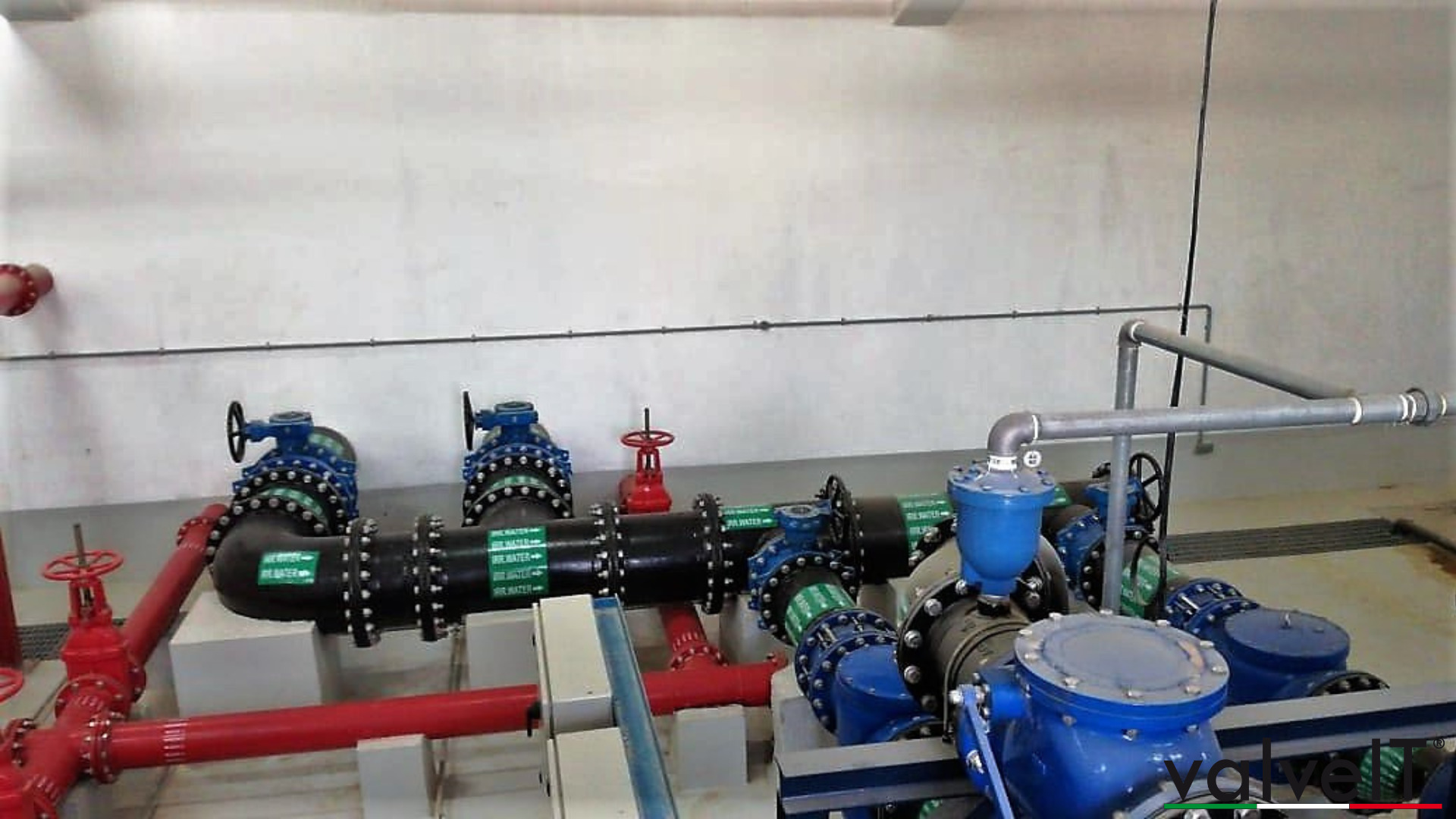

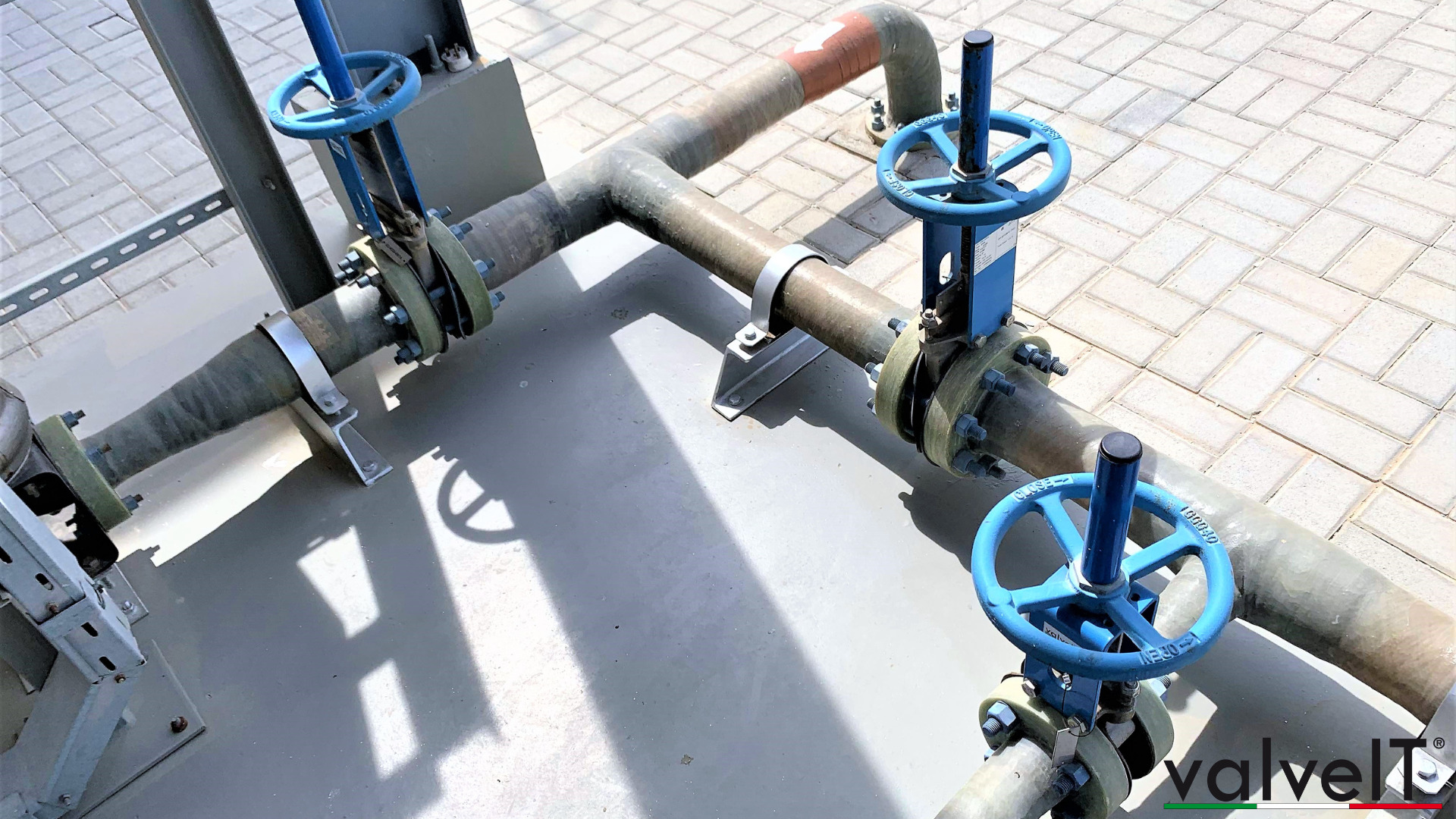

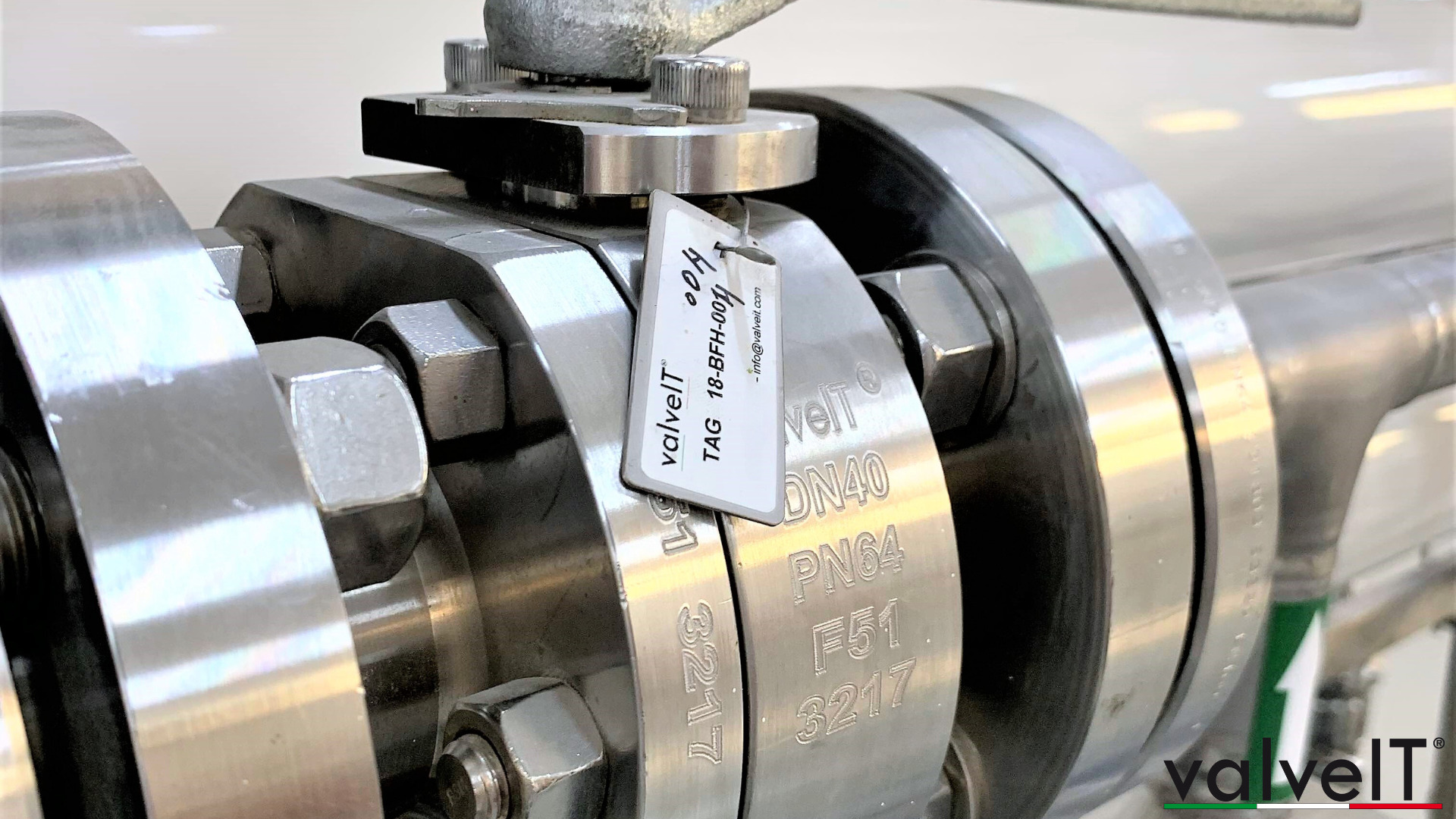

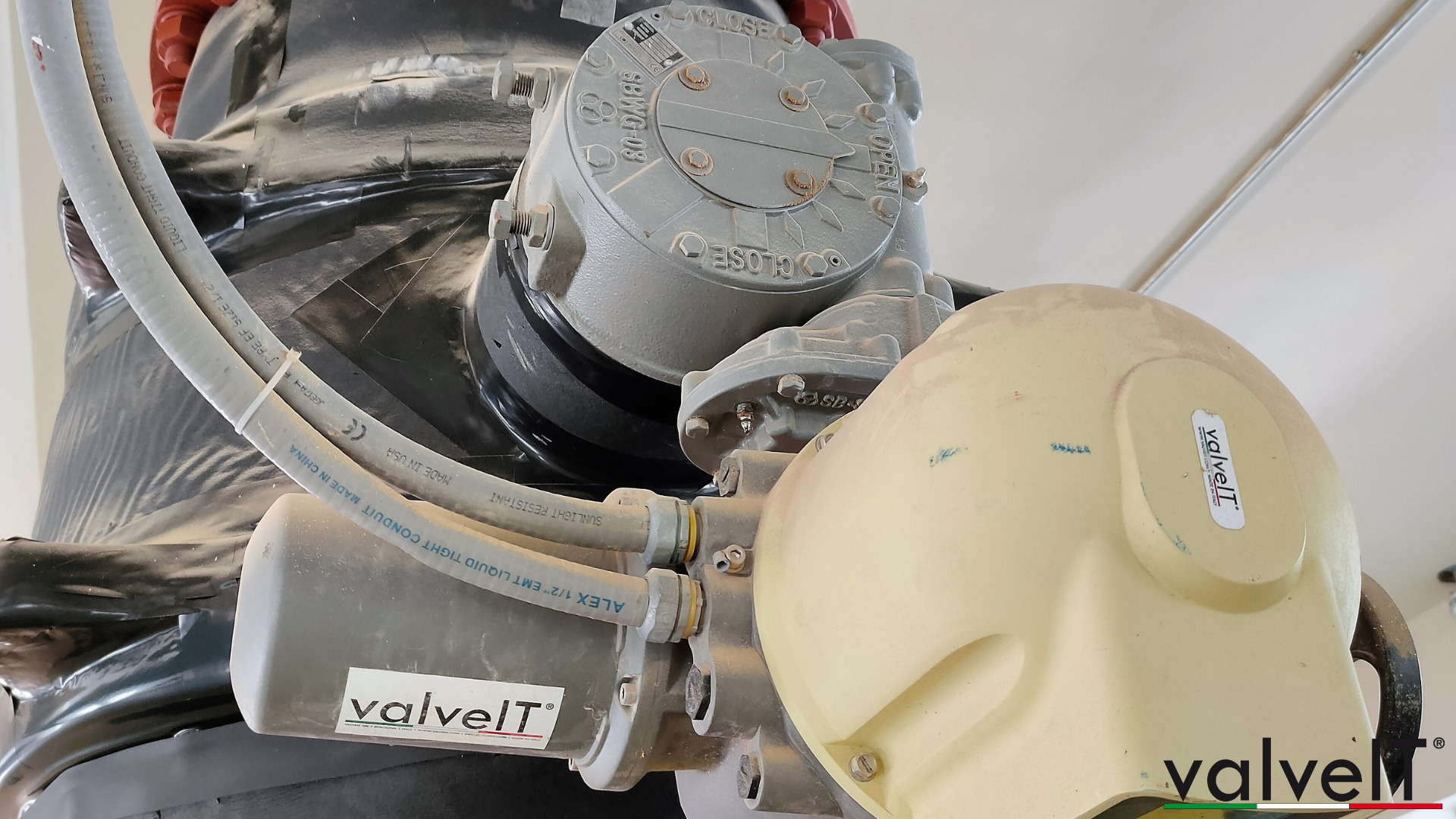

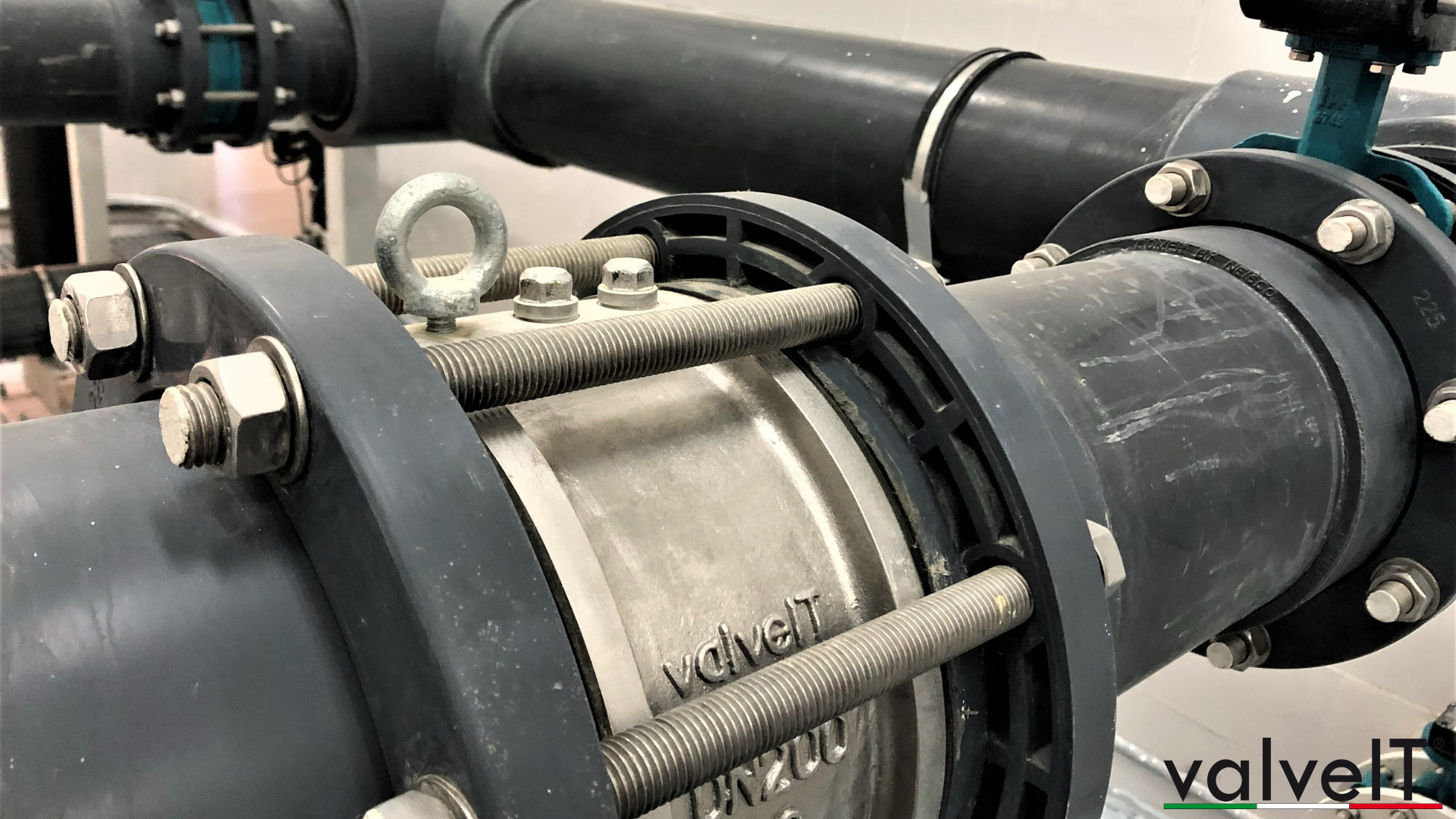

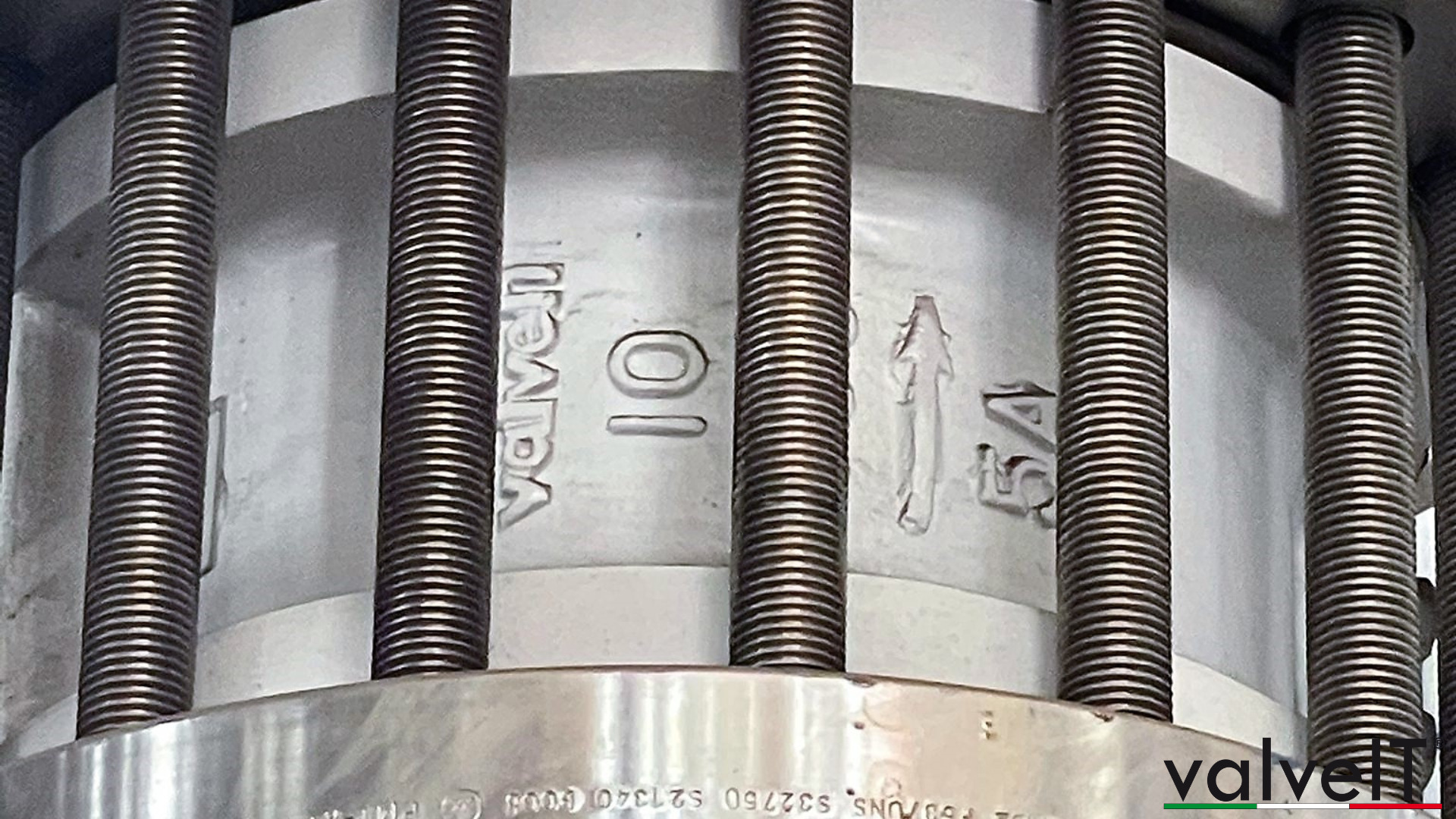

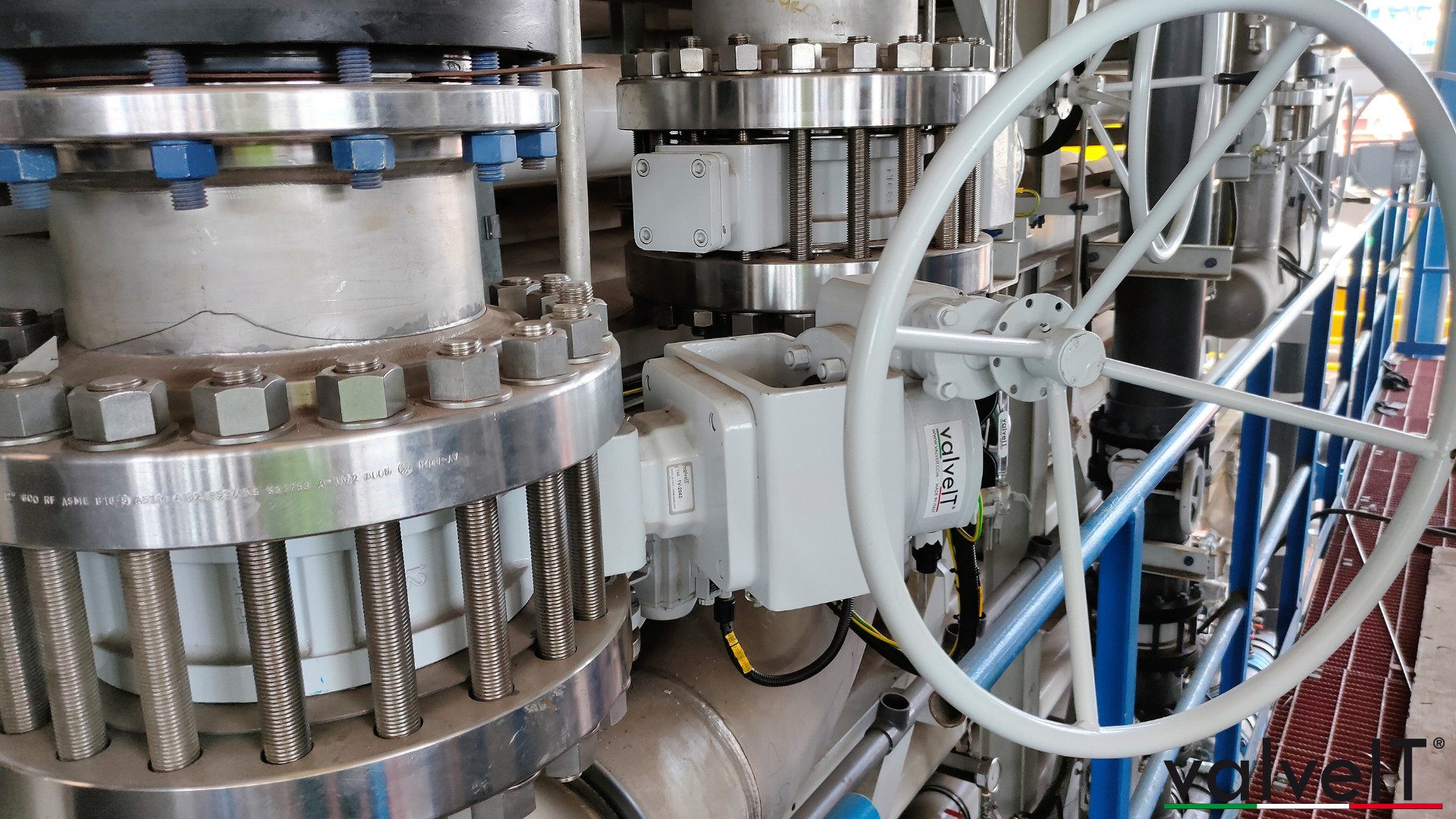

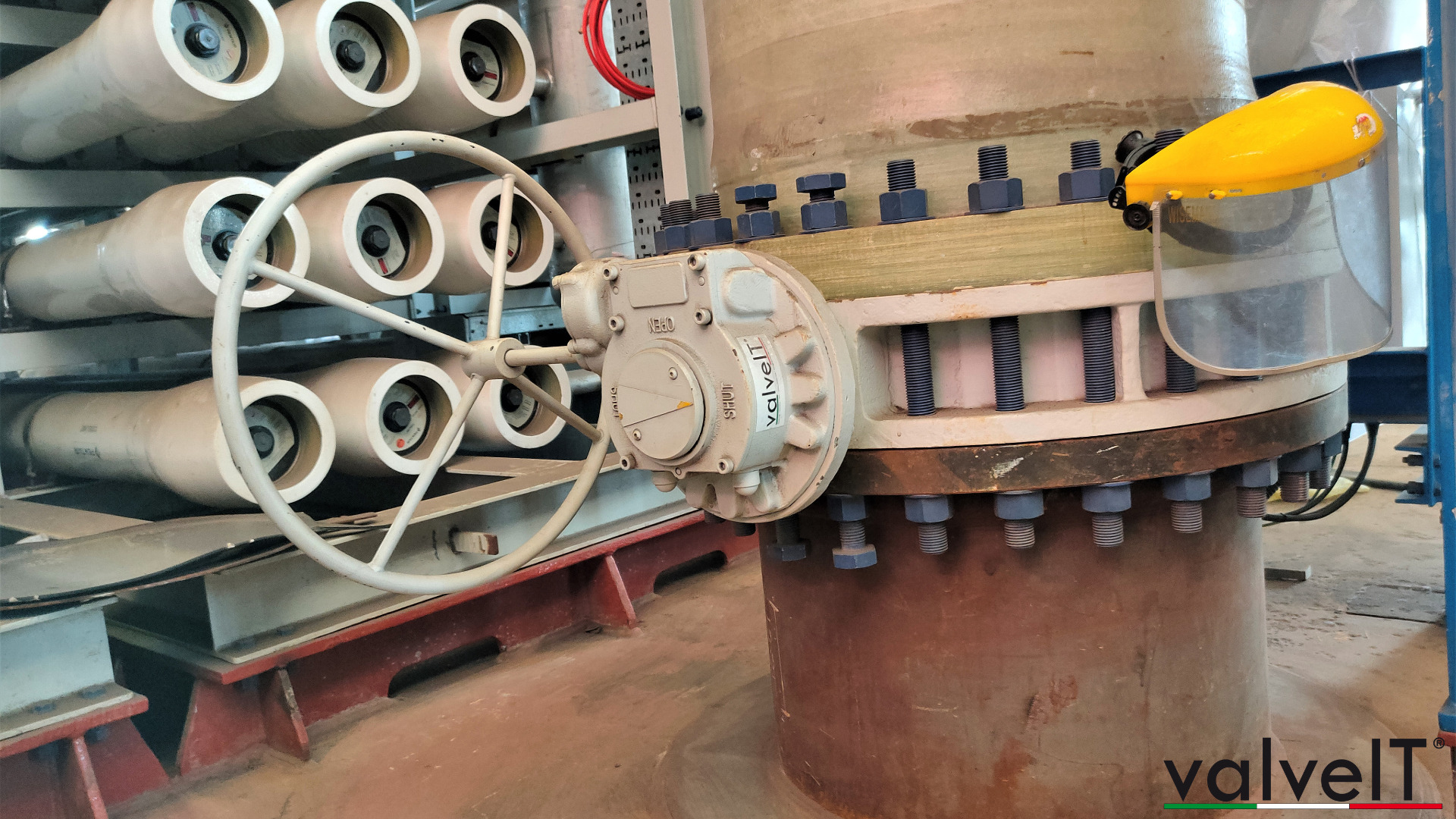

Once valveIT‘s valves have been properly assembled, a rigorous and comprehensive testing and inspection process to ensure the quality, performance, and reliability is performed. The testing and inspection procedures encompass both functional and hydrostatic tests, adhering to the EN 12266 standard. Additionally, the company offers Non-Destructive Testing (NDT) services, such as liquid penetrant, radiographic, positive material identification (PMI) and spark tests to meet specific project requirements.

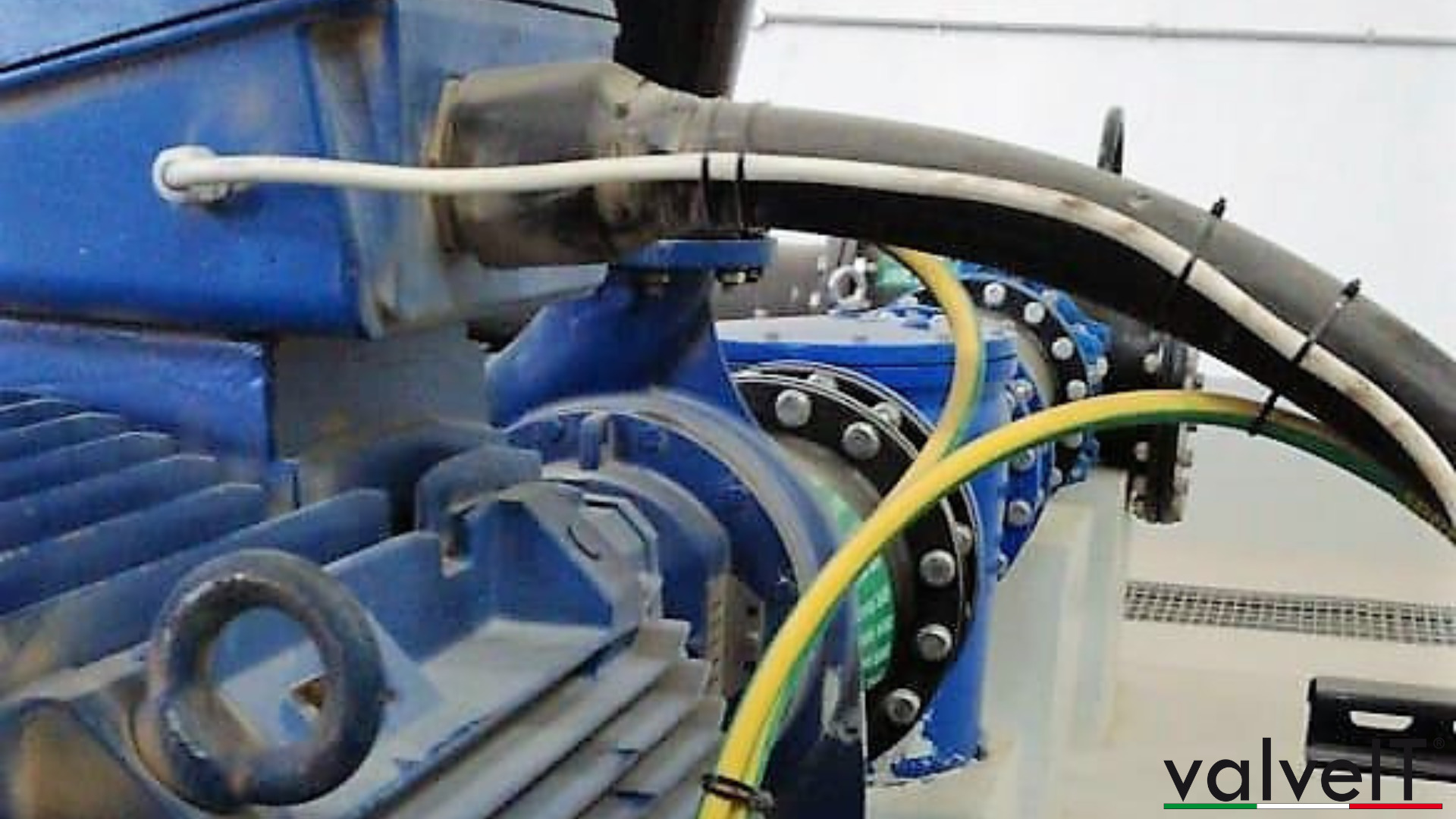

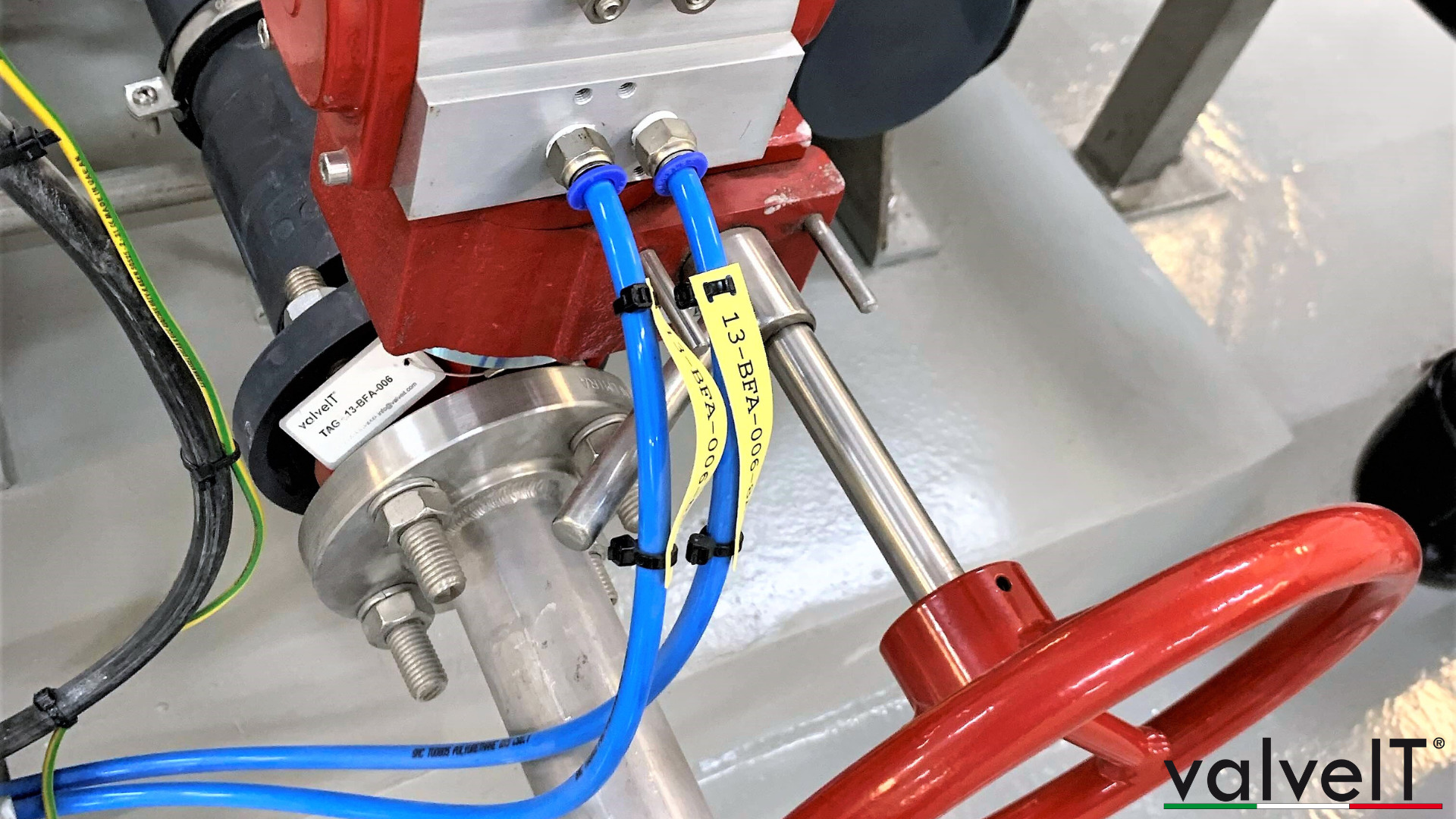

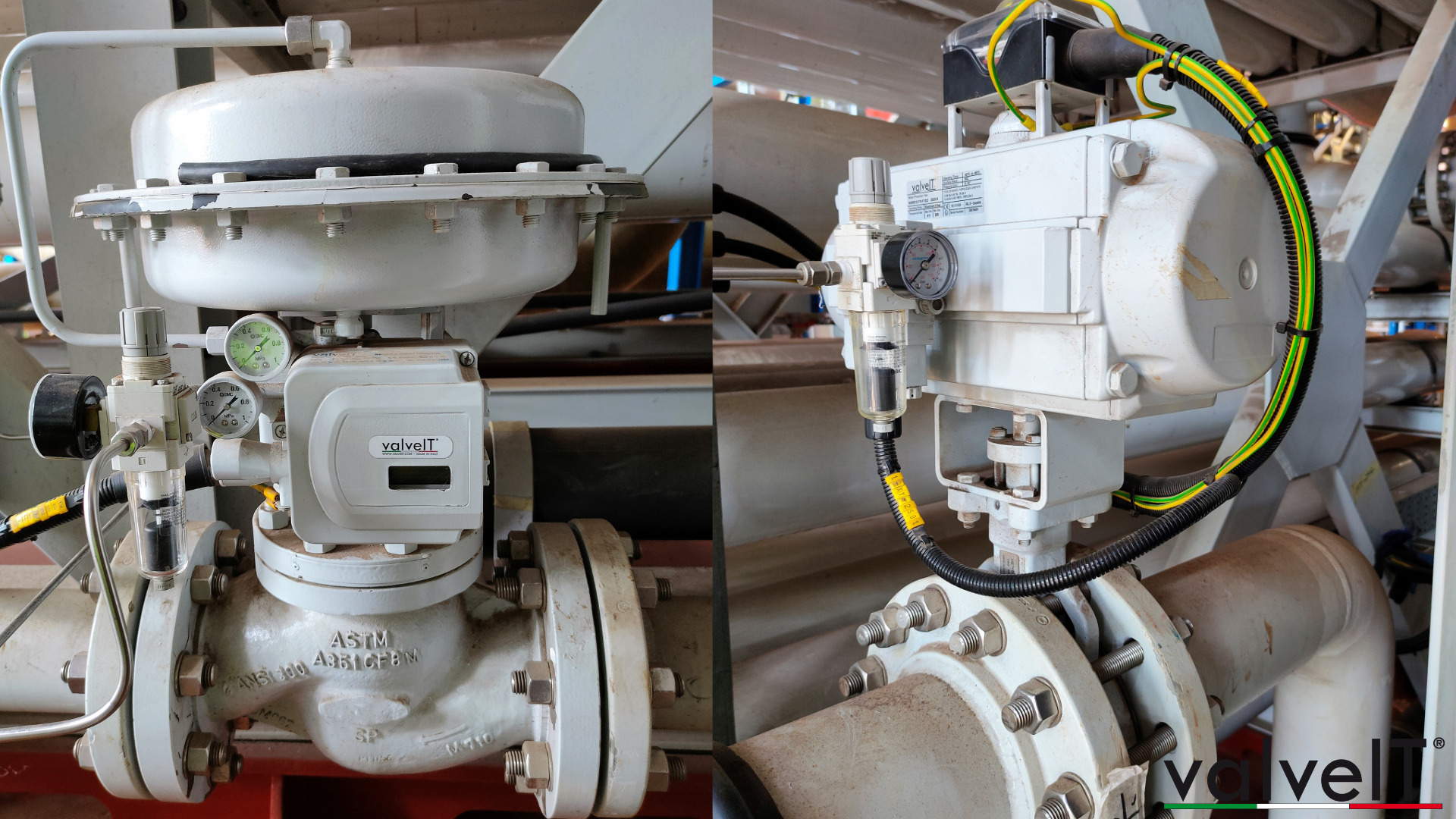

valveIT conducts functional tests to evaluate the valve’s performance and its ability to control fluid flow accurately. These tests involve operating the valve, checking its response to commands, and assessing its capability to handle different pressures.

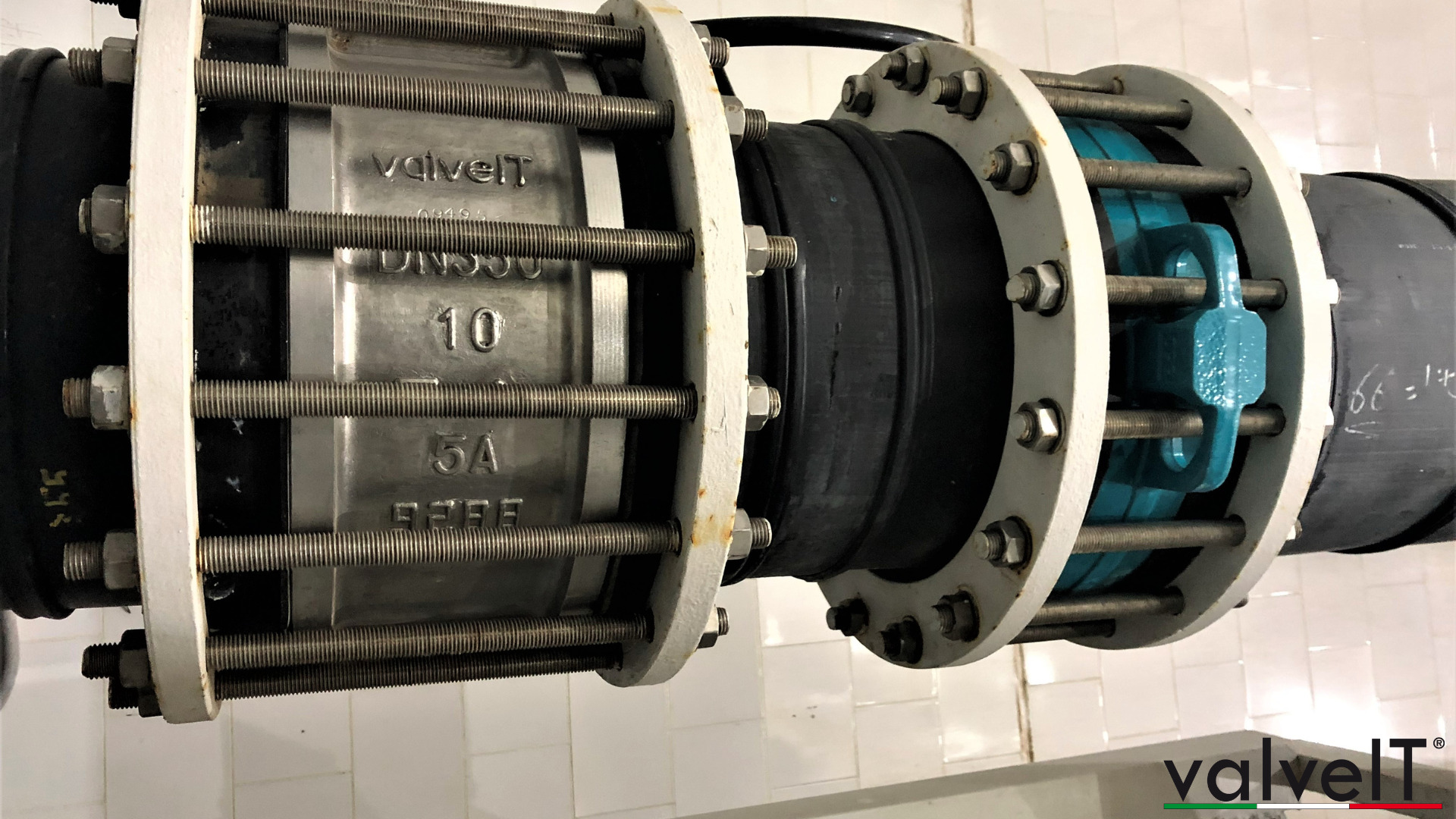

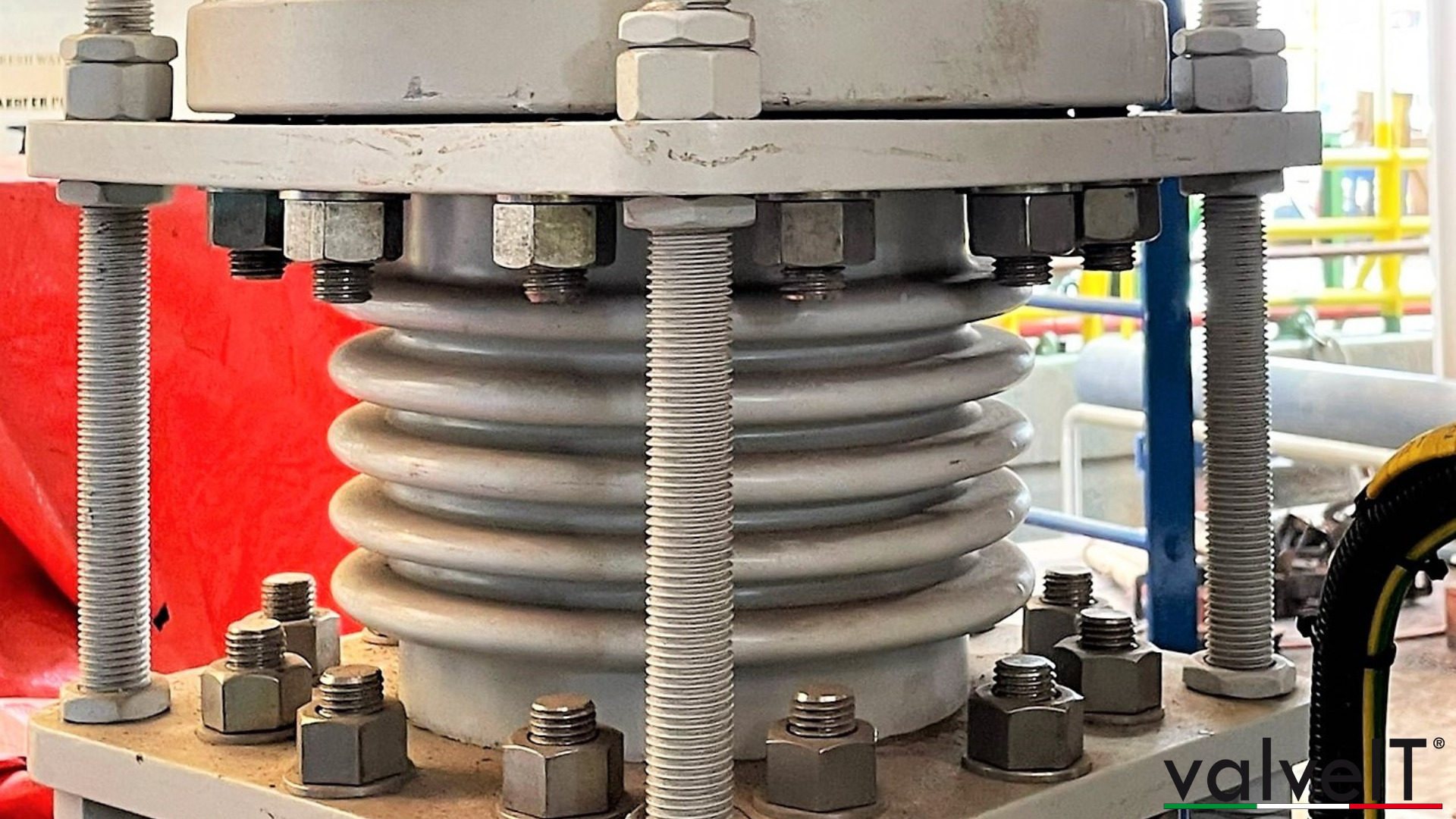

Hydrostatic testing is performed to assess the valve’s pressure resistance and integrity. During this test, the valve is subjected to pressures higher than its maximum nominal pressure. valveIT carefully monitors the valve’s response to these pressures, looking for any signs of leakage or structural failure. Hydrostatic tests validate that the valves can withstand the specified pressures and will function safely under demanding conditions.

Any deviations or irregularities detected during testing are addressed promptly, and necessary adjustments are made to ensure the valves meet the highest quality standards.